|

Key Industry 4.0 Technologies |

Definition |

|

Big Data Analytics |

Big data analytics is the process of examining and uncovering insights, patterns, and trends from large, complex data sets. It uses advanced analytical techniques, such as machine learning and data mining, to process and analyse vast amounts of structured and unstructured data. |

|

Industrial Internet of Things (IIoT) |

The Industrial Internet of Things (IIoT) is the use of internet-connected devices and sensors in industrial settings to collect and transmit real-time data. |

|

Cyber-physical Systems |

Cyber-physical systems (CPS) are integrated systems that combine physical and digital components to enable real-time communication and control. CPS are designed to improve efficiency, safety, and reliability in a wide range of industries, including transportation, manufacturing, and healthcare. |

|

Artificial Intelligence (AI) |

Artificial Intelligence (AI) refers to the development of computer systems that can perform tasks that typically require human intelligence, such as visual perception, speech recognition, decision-making, and language understanding. By analysing data and identifying patterns, machine learning algorithms enable AI systems to make predictions and decisions. Artificial intelligence is applied to a wide range of fields, including natural language processing, computer vision, robotics, and autonomous cars. AI systems can be classified into different categories, including supervised learning, unsupervised learning, reinforcement learning, active, and frugal learning. |

|

Additive Manufacturing |

A process called additive manufacturing (AM), also known as 3D printing, creates three-dimensional objects by layering materials until a final shape is obtained. Unlike traditional manufacturing processes, which involve subtracting or shaping material from a larger block, AM builds the object from the ground up, layer by layer. |

|

Augmented Reality (AR) |

The concept of augmented reality (AR) refers to adding digital elements to a real-world environment to enhance it or make it more interactive. In this type of environment, the physical world is combined with virtual objects or information using computer-generated graphics, sounds, and other sensory inputs. The use of AR is mainly centered on mobile devices or wearable technology, and it can be used for different purposes, such as gaming, education, marketing, and training. |

|

Simulation |

Using simulations is an effective way to test different scenarios or modify processes to provide evidence for decision-making. |

|

Blockchain |

Blockchain technology can facilitate secure and transparent transactions, data sharing, and supply chain management in various industries. With blockchain, companies can track the movement of goods and materials in real-time, improve inventory management, reduce costs, and enhance trust and transparency between business partners. |

|

Cloud Computing |

Cloud computing allows users to gain access to and use computer resources, such as servers, storage, databases, and software, through the Internet without having to install hardware or infrastructure locally. Third-party providers typically provide these resources as a service through various subscription models such as Software as a Service (SaaS), Platform as a Service (PaaS), and Infrastructure as a Service (IaaS). |

|

High Performance Computing |

High-speed data processing and complex calculations. |

|

Industrial Robots |

Industrial robots are automated, programmable, and capable of movement on three or more axes. |

|

Machine-to-Machine (M2M) |

M2M, or machine-to-machine, refers to direct communication between two or more devices without the need for human interaction. By using wireless or wired communication channels, these devices can exchange data and perform actions automatically. A variety of industrial and commercial applications are using M2M, including fleet management, home automation, and remote monitoring and control. |

|

Manufacturing Execution Systems (MES) |

The Manufacturing Execution System (MES) is an automated system designed to track, monitor, and control manufacturing operations. Through MES systems, manufacturers can see and control manufacturing processes in real time, improve quality, reduce waste, and increase efficiency. Integration between MES and Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) provides a comprehensive view of manufacturing operations. |

|

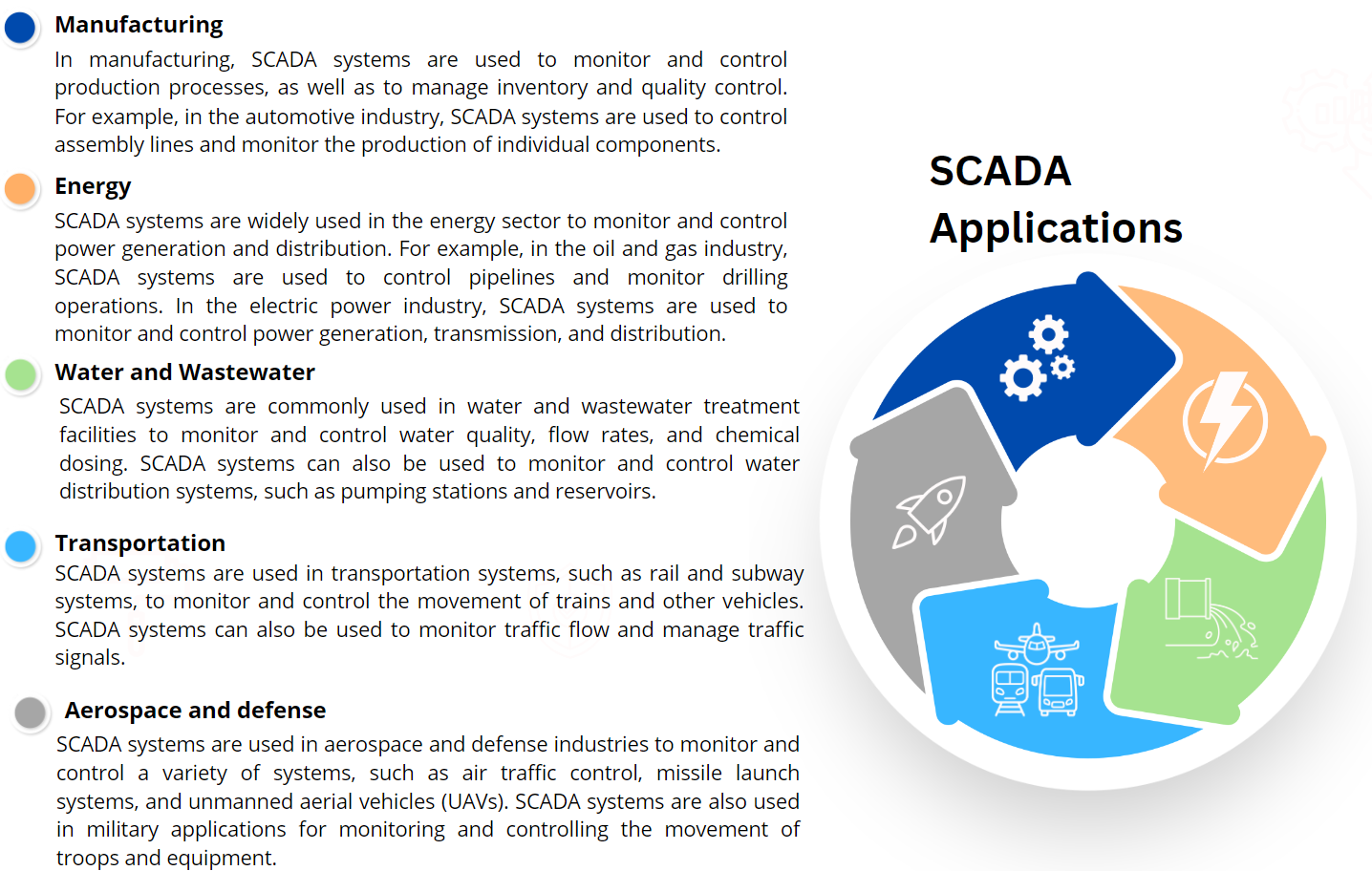

Supervisory Control and Data Acquisition Systems (SCADA) |

SCADA (Supervisory Control and Data Acquisition) systems are computer-based control systems used to monitor and control industrial processes, such as power generation, manufacturing, and transportation. These systems are used to gather real-time data from sensors and other devices, and then transmit that data to a central control center where it can be analysed and used to make decisions about how to manage the process. SCADA systems typically include software applications, human-machine interfaces, and communication networks that allow operators to remotely control and monitor processes in real-time. |

|

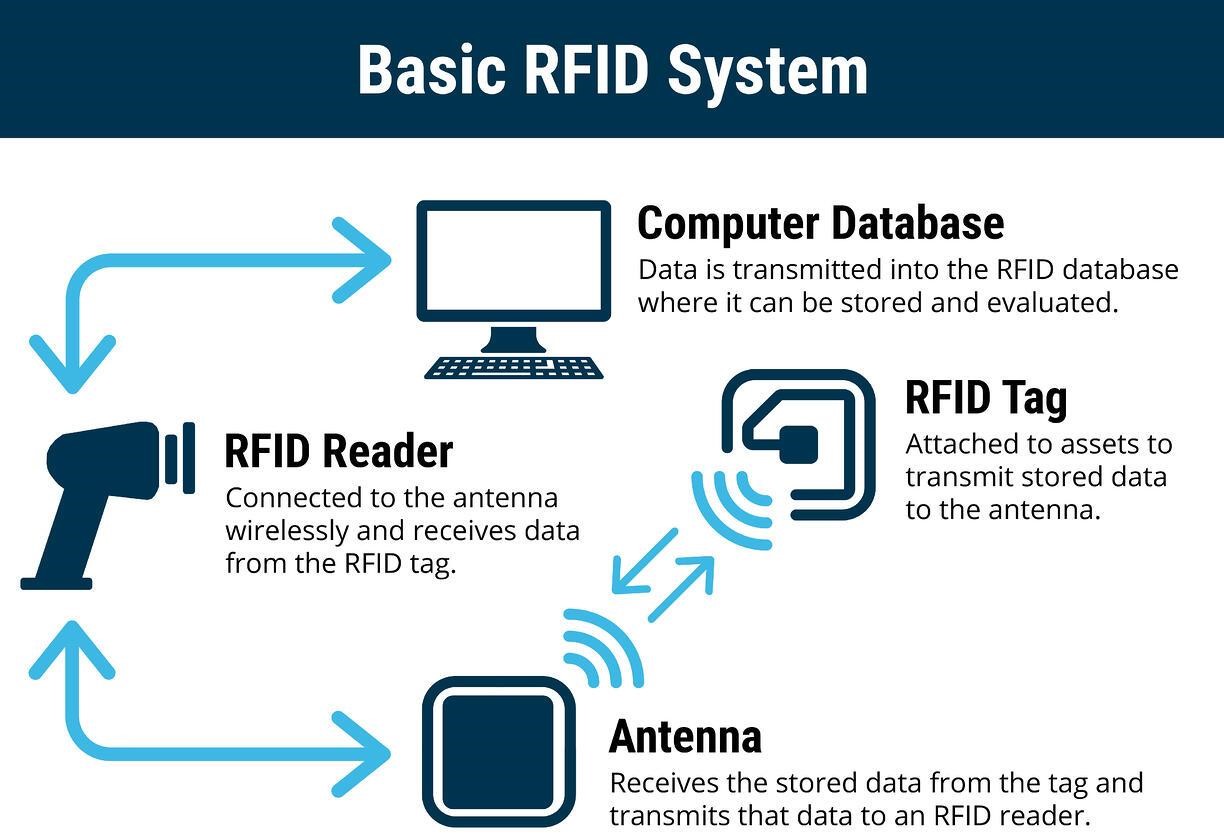

Radio-frequency identification (RFID) |

Using radio frequency identification or RFID, it is possible to identify and track objects by using signals generated by radio waves. An RFID system consists of two components: a reader which is attached to the object to be tracked along with a tag (or label) which is attached to the tag. |

|

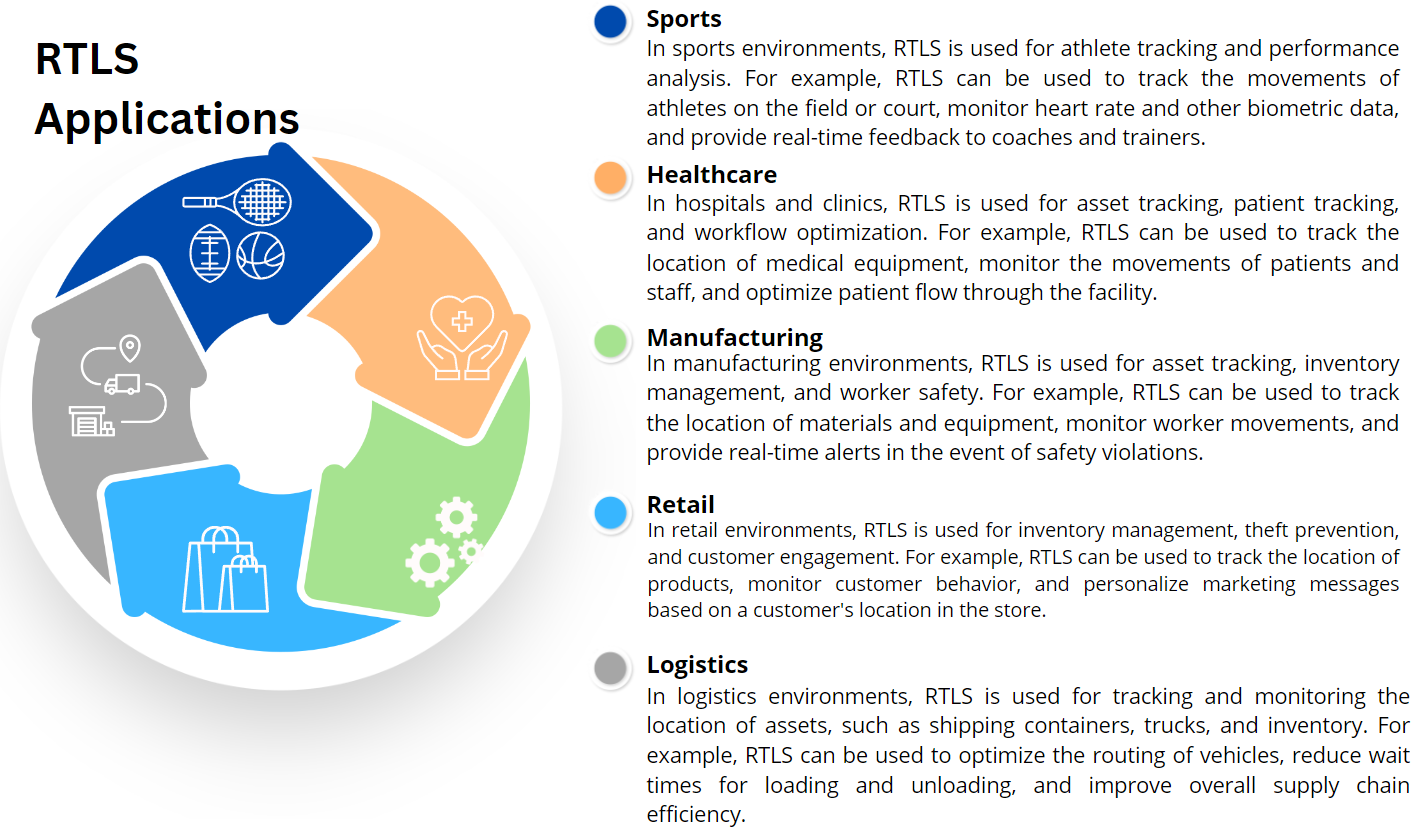

Real-time Locating System (RTLS) |

RTLS is a technology used to automatically identify and track the location of objects or people in real-time using sensors, RFID tags, or other types of wireless communication. |

|

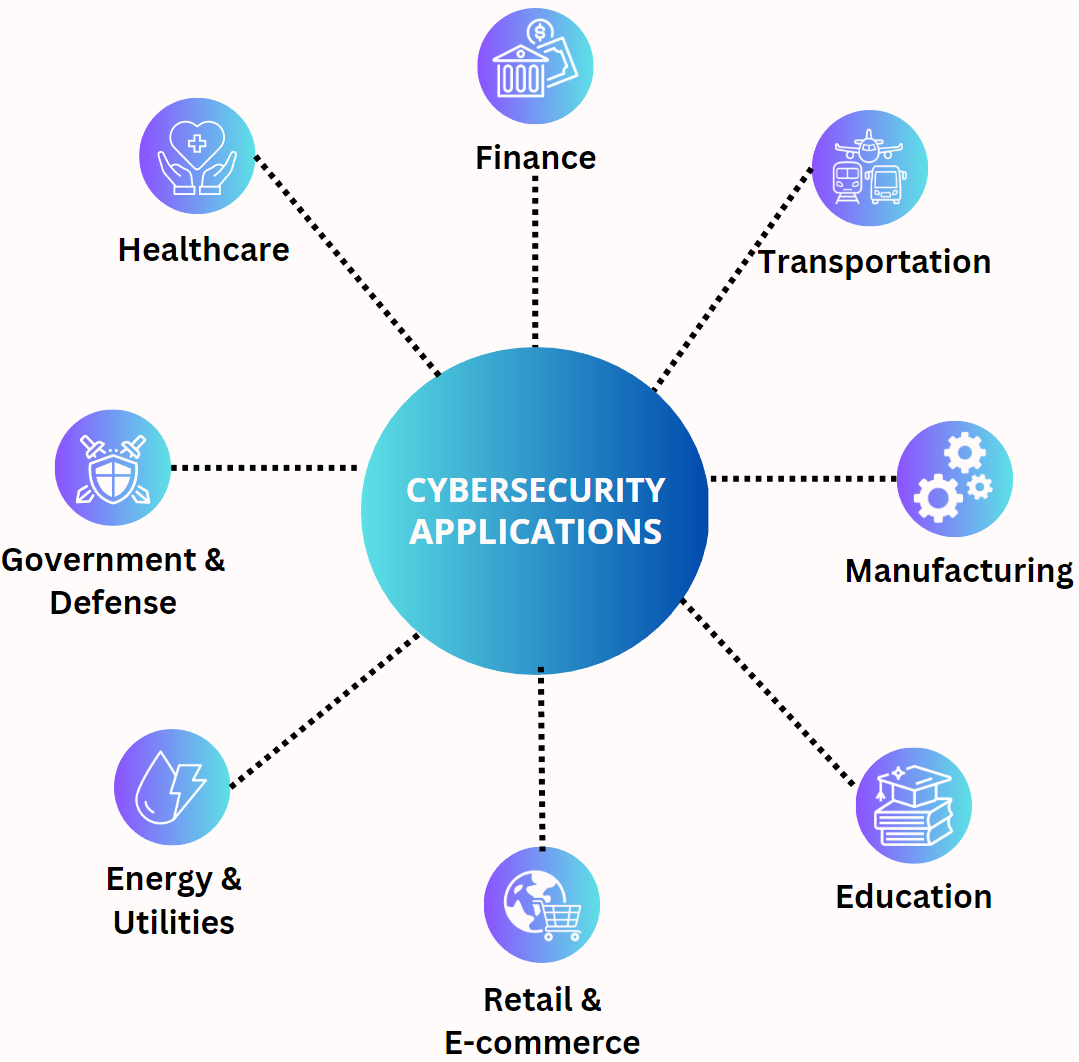

Cybersecurity |

Cybersecurity is the protection of internet-connected systems such as hardware, software, and data from cyberthreats. |

|

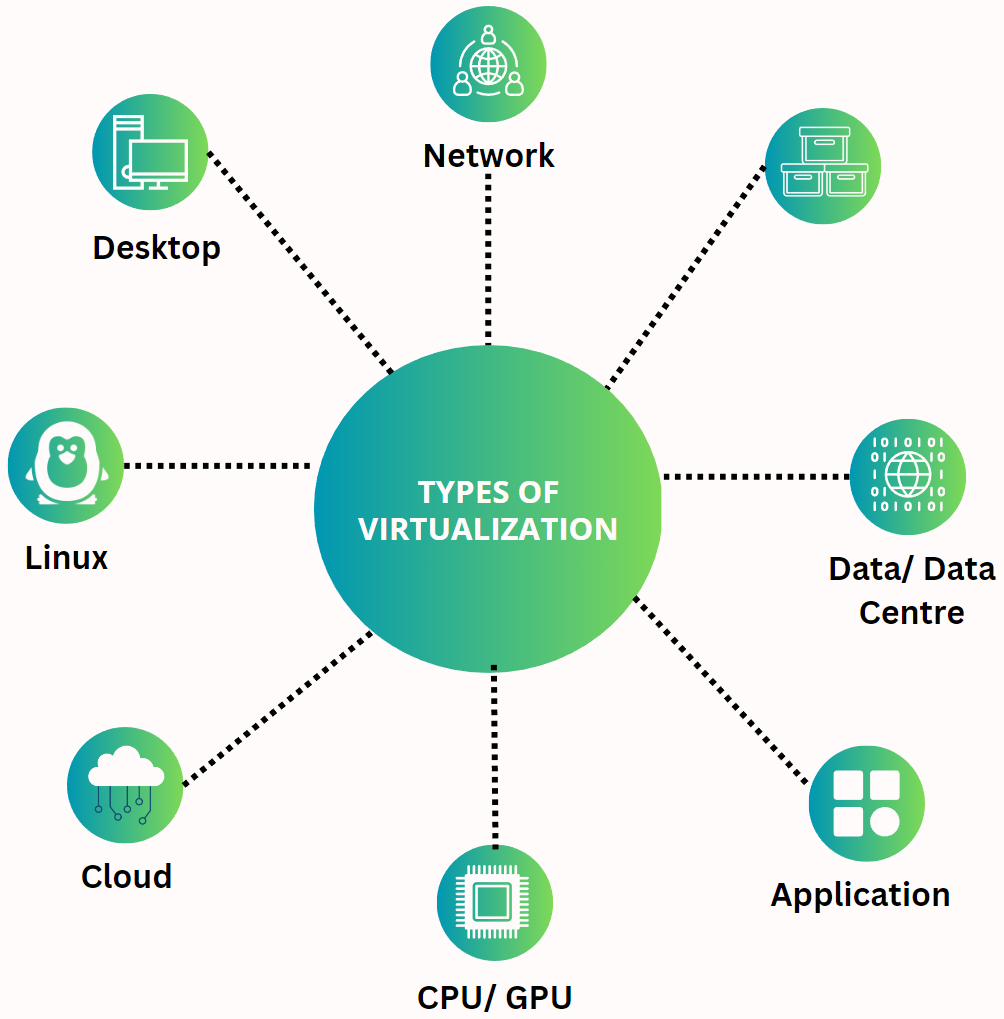

Virtualization Technologies |

The concept of virtualization allows multiple virtual machines to run on one physical machine, maximizing hardware resources and reducing costs. It provides a layer of abstraction between the hardware and software, allowing multiple operating systems and applications to run on the same physical server. Virtualization technologies enable cloud computing to provide computing resources to users on a pay-per-use basis. |

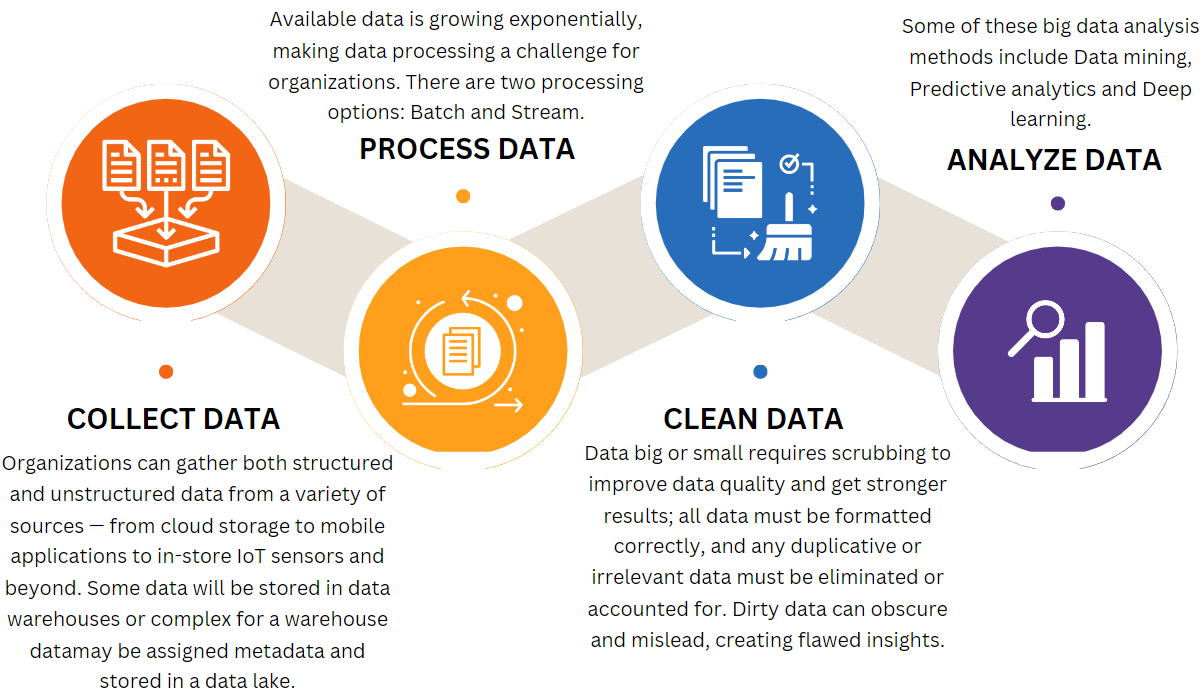

Big Data Analytics

Big Data Analytics has become a key technology in Industry 4.0 due to its ability to collect, process, and analyse large volumes of data from various sources, leading to valuable insights, improved decision-making, and enhanced operational efficiency. Big Data Analytics is crucial in Industry 4.0 as it enables organizations to harness the power of data and turn it into actionable insights, helping them identify patterns and trends that would be difficult or impossible to detect using traditional methods.

Big Data Analytics presents numerous benefits, including improved decision making by providing businesses with insights that are derived from large volumes of data. In addition, Big Data Analytics can help businesses automate and streamline their processes, which can improve efficiency and productivity. Manufacturers, for instance, can utilize data analytics to optimize their production processes and reduce waste, which can save time and money. Big Data Analytics can also offer an enhanced customer experience as they help businesses understand their customers better and personalize their offerings based on customer preferences and behaviour. Moreover, this key Industry 4.0 technology can help businesses identify and manage risks more effectively. For example, financial institutions can use data analytics to detect fraudulent transactions and prevent financial crimes. Finally, Big Data Analytics can help businesses identify new business opportunities and revenue streams. For example, companies can use data analytics to analyse market trends and consumer behaviour to identify new product opportunities. This can help them stay ahead of the competition and increase revenue.

The STOA in Big Data Analytics involves a combination of technologies, techniques, and tools that enable organizations to derive value from their data assets. It is also characterized by a growing focus on real-time data processing, which can be crucial in industries such as finance and healthcare, the integration of structured and unstructured data, and the use of artificial intelligence and machine learning to automate data analysis and decision-making. Additionally, there is a growing emphasis on data privacy and security, as organizations seek to balance the benefits of Big Data Analytics with the need to protect sensitive data. Some of the big data trends, their benefits and the respective challenges they are addressing, are presented in the following Table.

Key Trends in Big Data Analytics

|

Key Trend |

Details |

|

Adoption of Cloud-based Big Data Analytics |

Cloud-based big data analytics solutions are gaining momentum due to their scalability, flexibility, and cost-effectiveness. These involve the use of cloud-based platforms such as Amazon Web Services, Microsoft Azure, and Google Cloud Platform to store and process large volumes of data. |

|

Integration of structured and unstructured data |

Organizations are increasingly turning to Natural Language Processing (NLP) and machine learning algorithms that can identify patterns and relationships in large, unstructured datasets. |

|

Real-time Data Processing |

Real-time data processing is becoming increasingly important, as businesses need to make quick decisions based on rapidly changing data. To address this challenge, many organizations are adopting distributed computing frameworks like Apache Hadoop and Apache Spark, which allow for parallel processing of large datasets across clusters of computers. |

|

Artificial Intelligence (AI) and Machine Learning (ML) |

AI and ML are becoming integral to big data analytics, as they help to analyse large volumes of data more efficiently and accurately. |

|

Edge Computing |

Edge computing involves processing data at or near the source, which helps to reduce latency and increase processing speed. This trend is gaining traction in big data analytics. |

|

Data Privacy and Security |

With the increasing volume of data being collected, data privacy and security are becoming major concerns for organizations. Ensuring the security and privacy of data is a key trend in Big Data Analytics. To address these concerns, new regulations like the General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA) have been introduced, placing greater emphasis on data governance and transparency. |

|

Data Governance and Management |

Effective data governance and management are critical for the success of Big Data Analytics initiatives. Organizations are focusing on developing strategies to manage their data effectively. |

|

Visualization and Storytelling |

Visualization and storytelling techniques are becoming increasingly important in big data analytics, as they help to communicate complex data insights to non-technical stakeholders. |

Overall, Big Data Analytics has the potential to transform businesses and drive innovation. By leveraging the power of data, businesses can make better decisions, improve efficiency and productivity, enhance the customer experience, manage risks more effectively, and identify new business opportunities.

Industrial Internet of Things (IIoT)

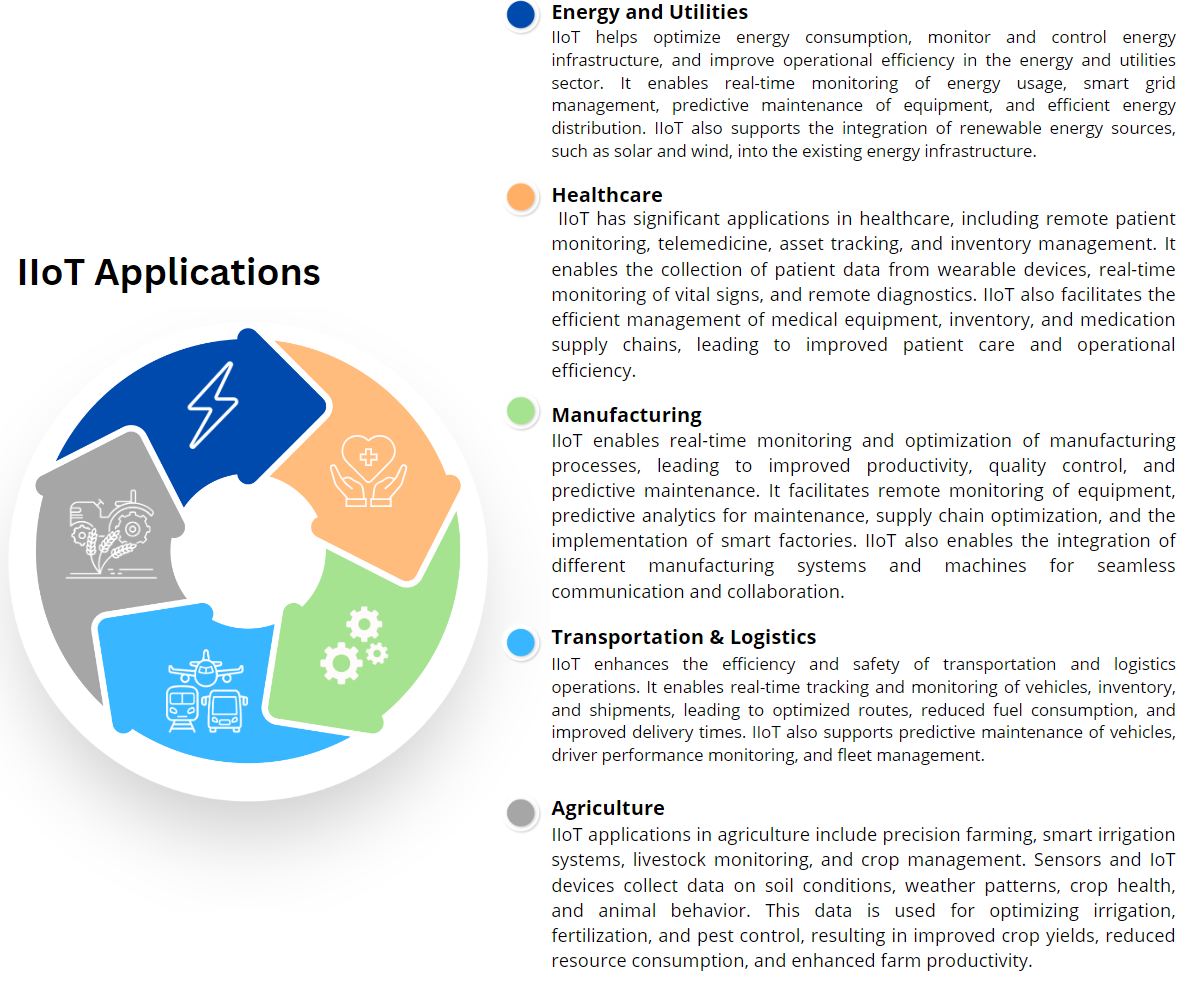

The Industrial Internet of Things (IIoT) refers to the network of interconnected devices, sensors, machines, and systems in industrial settings that enables data exchange and automation for improved operational efficiency and decision-making. IIoT leverages advanced technologies such as cloud computing, big data analytics, and machine learning to enable real-time data collection, analysis, and control in industrial processes.

One of the key features of IIoT is the ability to connect and monitor various devices and systems, allowing for seamless communication and data sharing across the industrial ecosystem. This connectivity enables the collection of vast amounts of data from different sources, such as sensors embedded in machines, production equipment, and even wearable devices worn by workers.

The data generated by IIoT devices is processed and analysed using advanced analytics techniques. This enables organizations to gain valuable insights into their operations, identify patterns, optimize processes, and make data-driven decisions. By leveraging predictive analytics, IIoT can enable predictive maintenance, reducing downtime and increasing the lifespan of industrial equipment.

IIoT also plays a significant role in enabling automation and control in industrial environments. Through the integration of devices and systems, organizations can remotely monitor and control processes, equipment, and even entire factories. This enables increased efficiency, reduced human error, and improved safety in industrial operations. The Industrial Internet of Things (IIoT) has diverse applications across various industries and some of them are presented in the Figure below.

IIoT Application in different Industries

Furthermore, IIoT facilitates the integration of physical systems with digital systems, enabling the convergence of operational and information technology. This integration allows for the seamless exchange of data between different systems, creating synergies and unlocking new possibilities for industrial optimization and innovation. Some of the key trends in IIoT are presented in the following table.

Key Trends in IIoT

|

Key Trend |

Details |

|

Edge computing |

With the increasing volume of data generated by IIoT devices, there is a growing need to process and analyse data closer to the edge of the network, near the data source. Edge computing allows for faster data processing, reduced latency, and improved real-time decision-making by moving computational power closer to the devices. |

|

AI and machine learning integration |

The integration of AI and machine learning algorithms with IIoT systems enables advanced data analytics, predictive maintenance, anomaly detection, and optimization of industrial processes. These technologies enable the identification of patterns, trends, and correlations in complex industrial data, leading to improved operational efficiency and reduced downtime. |

|

Enhanced cybersecurity |

As IIoT networks expand, there is an increased risk of cyber threats and attacks. Ensuring the security and integrity of IIoT systems has become a top priority. Advancements in secure communication protocols, authentication mechanisms, and encryption techniques are being developed to protect IIoT networks from unauthorized access and data breaches. |

|

Digital twins |

Digital twins are virtual replicas of physical assets or processes that are continuously updated with real-time data from sensors. By integrating IIoT data with digital twin technology, organizations can gain valuable insights into asset performance, conduct virtual simulations, and optimize operations. Digital twins enable predictive maintenance, improved asset management, and faster troubleshooting. |

|

Industry-specific IIoT solutions |

There is a growing trend of industry-specific IIoT solutions tailored to the unique requirements of different sectors, such as manufacturing, energy, healthcare, and transportation. These solutions are designed to address specific challenges and leverage IIoT technologies to improve efficiency, productivity, and safety within those industries. |

Cyber-physical Systems

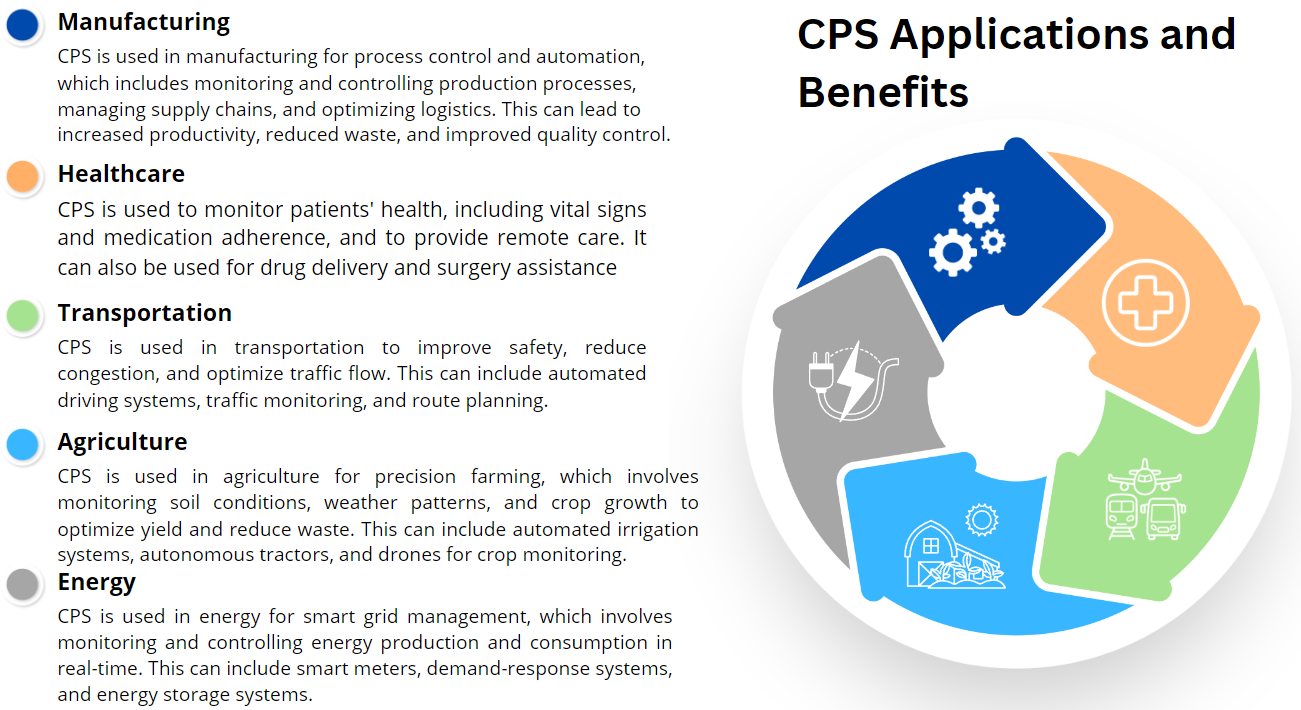

Cyber-physical systems (CPS) are a class of engineered systems that integrate physical processes with computing and communication technologies. They are designed to sense, monitor, and control physical processes in real-time, and have applications in a wide range of domains, including manufacturing, healthcare, transportation, agriculture and energy systems.

CPS Applications and Benefits in different Industries

In recent years, there has been a growing interest in CPS due to the increasing availability of cheap and reliable sensors, the rise of the Internet of Things (IoT) paradigm, and the growing demand for automation and smart systems. One key trend in CPS is the integration of machine learning algorithms and artificial intelligence techniques to enable autonomous decision-making and behaviour adaptation. This trend is particularly relevant in applications such as autonomous vehicles, where intelligent agents need to make decisions based on real-time sensory data and environmental feedback.

Another trend in CPS is the adoption of blockchain technology to enhance security, trust, and transparency in distributed systems. Blockchain-based CPS can provide secure and auditable data exchanges, facilitate secure transactions between devices, and enable secure and decentralized control of physical systems.

In addition, the development of 5G networks is expected to have a significant impact on CPS, as it will enable high-speed and low-latency communication between devices, and facilitate the integration of large-scale and complex systems. The use of 5G in CPS can enable the deployment of real-time applications, such as remote surgery, autonomous vehicles, and industrial automation, and improve the reliability and scalability of these systems.

Overall, the state-of-the-art in CPS research and development is characterized by a multidisciplinary approach that integrates principles from engineering, computer science, mathematics, and physics. The key challenges in CPS include ensuring the security and privacy of sensitive data, managing the complexity of large-scale systems, and ensuring the robustness and reliability of the physical processes.

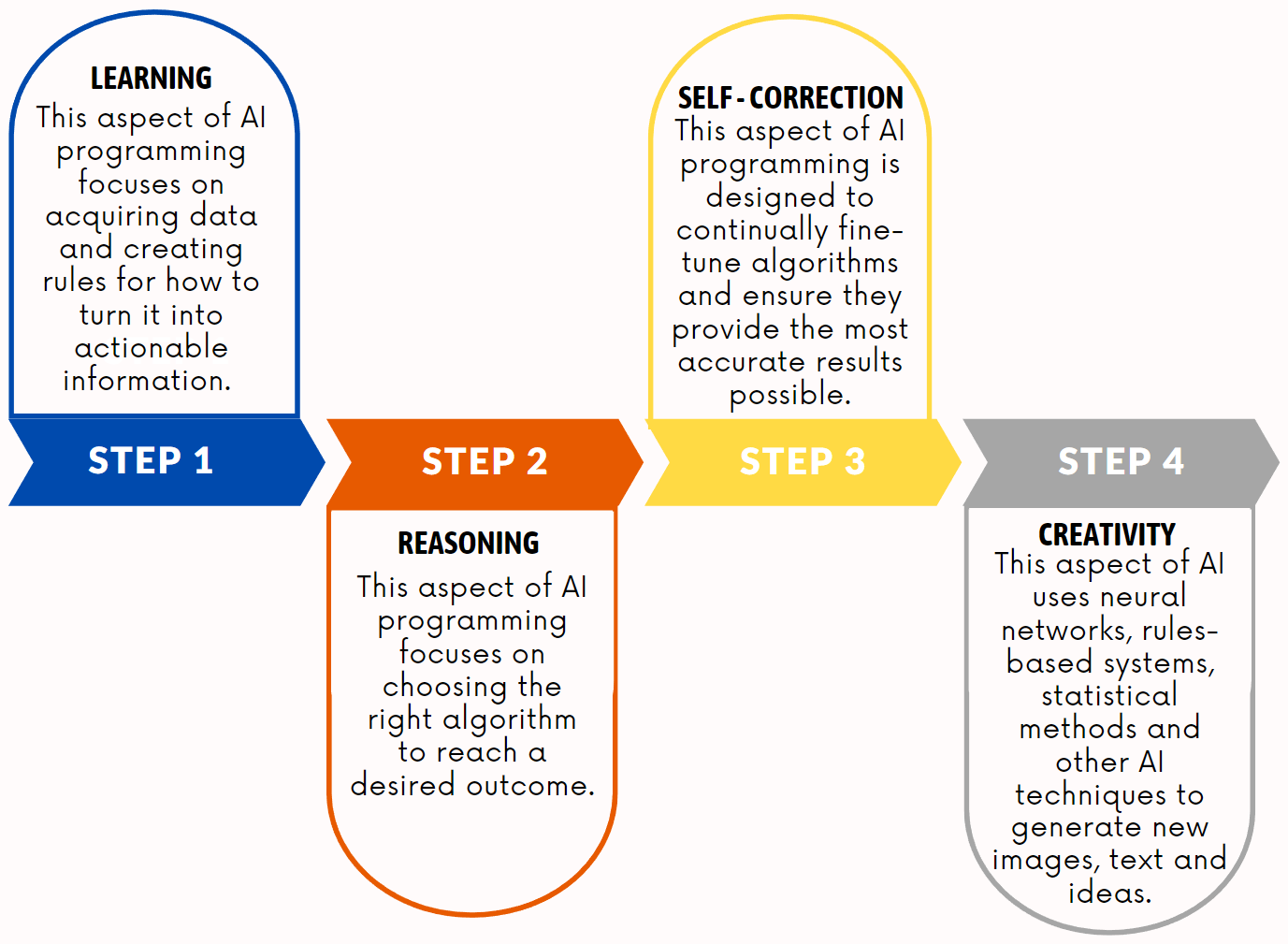

Artificial Intelligence (AI)

Artificial Intelligence (AI) is a rapidly evolving field that involves the development of intelligent agents capable of performing tasks that typically require human-level intelligence. AI encompasses a range of subfields, including machine learning, natural language processing, robotics, computer vision, and cognitive computing. Recent advances in deep learning algorithms and the availability of massive amounts of data have fuelled significant progress in AI applications, such as image recognition, speech recognition, natural language understanding, and autonomous driving. Some of the key trends in AI are presented in the following table.

Key Trends in AI

|

Key Trend |

Details |

|

Continued growth of deep learning |

Deep learning, a subset of machine learning, has made significant progress in recent years and is expected to continue to grow in popularity. This is due to the ability of deep learning algorithms to process large amounts of data and identify complex patterns. |

|

Increased focus on explainable AI |

Explainable AI is an important research area aimed at improving the transparency and interpretability of AI systems. This is critical for ensuring that AI is trusted and accepted by users, particularly in high-stakes applications such as healthcare and finance. |

|

Advances in natural language processing |

Natural language processing (NLP) is an important area of AI that deals with the interaction between computers and human language. Recent advances in NLP have led to significant improvements in language understanding and generation, making it possible to create more sophisticated chatbots and virtual assistants. |

|

AI-driven automation |

AI-driven automation is a trend that involves the use of AI to automate routine tasks in various industries, such as manufacturing, transportation, and healthcare. This is expected to lead to increased productivity and efficiency in these industries. |

|

AI for social good |

There is an increasing focus on using AI for social good, such as in healthcare, education, and environmental sustainability. This trend involves leveraging AI to address some of the world’s most pressing challenges, such as climate change and poverty. |

|

Advancements in autonomous systems |

Autonomous systems, such as self-driving cars and drones, are becoming increasingly sophisticated, thanks to advancements in AI. This is expected to lead to increased safety, efficiency, and convenience in various industries. |

|

Increased focus on AI ethics |

AI ethics is a growing field that deals with the ethical considerations surrounding the development and use of AI. As AI becomes more widespread, there is a need to address issues such as bias, privacy, and accountability. |

|

Edge computing for AI |

Edge computing is a trend that involves processing data on local devices, rather than sending it to a centralized server. This is becoming increasingly important in the context of AI, as it allows for real-time processing and reduced latency. |

In general, AI systems work by ingesting large amounts of labeled training data, analyzing the data for correlations and patterns, and using these patterns to make predictions about future states. In this way, a chatbot that is fed examples of text can learn to generate lifelike exchanges with people, or an image recognition tool can learn to identify and describe objects in images by reviewing millions of examples. New, rapidly improving generative AI techniques can create realistic text, images, music and other media.

AI has been effectively used in business to automate tasks done by humans, including customer service work, lead generation, fraud detection and quality control. AI has also made significant contributions to healthcare, including drug discovery, medical imaging analysis, and personalized medicine. AI algorithms have been shown to outperform traditional methods in diagnosing diseases such as skin cancer and detecting anomalies in medical images. AI has also been used to develop personalized treatment plans for cancer patients based on their genetic makeup. AI has also been applied in the financial sector to detect fraud, automate trading, and analyse credit risk. In addition, AI has been used to improve customer service in industries such as retail, hospitality, and transportation. Chatbots and virtual assistants have become increasingly popular, providing 24/7 customer support and personalized recommendations.

However, there are also challenges associated with AI, such as bias, ethics, and explainability. Bias can be introduced into AI systems if the training data is not representative of the population. Ethics involves considering the impact of AI on society and addressing issues such as job displacement and privacy. Explainability refers to the ability to understand how an AI system arrived at a particular decision, which is critical in domains such as healthcare and finance.

Additive Manufacturing

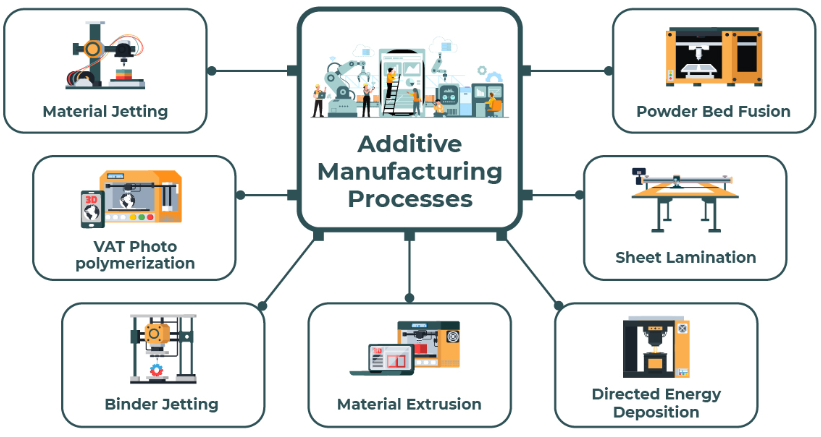

Additive Manufacturing (AM) is a revolutionary manufacturing process that builds objects by adding material layer-by-layer instead of cutting or shaping it from a block of material. AM has become increasingly popular in recent years, with applications ranging from rapid prototyping to medical implants and aerospace components.

7 Types of Additive Manufacturing

One of the main advantages of AM is its ability to create complex geometries that would be impossible or difficult to produce with traditional manufacturing methods. This has made AM particularly popular in the aerospace industry, where lightweight and complex parts can be produced with high precision and efficiency.

Another benefit of AM is its ability to reduce material waste and energy consumption, as the process only uses the necessary amount of material required to produce the part. This makes AM a more sustainable manufacturing method compared to traditional subtractive manufacturing methods.

AM is a rapidly evolving field, and new techniques and materials are being developed continuously. Some of the most recent advancements in AM include the use of multi-material printing, which allows for the creation of parts with different properties and functionalities, and the development of new metal alloys that can be printed with high accuracy and precision.

Furthermore, the use of machine learning and artificial intelligence in AM is becoming increasingly popular, allowing for faster and more efficient design and production processes. For example, machine learning algorithms can optimize the design of a part for AM, reducing material usage and improving performance.

There are several key trends in additive manufacturing (AM) that are shaping the industry and its future as shown in the following Table.

Key Trends in AM

|

Key Trend |

Details |

|

Increased adoption in production |

As AM technologies continue to improve and costs decrease, more companies are adopting AM for production. This is particularly true in the aerospace, medical, and automotive industries. |

|

Development of new materials |

As the demand for high-performance and functional materials increases, researchers are developing new materials that can be used in AM processes. For example, new metal alloys and composites are being developed that have improved strength, durability, and thermal properties. |

|

Advances in hybrid manufacturing |

Hybrid manufacturing combines AM with traditional subtractive manufacturing techniques to create parts that have the benefits of both. This allows for more efficient and cost-effective production of complex parts. |

|

Integration of AM with Industry 4.0 technologies |

The integration of AM with technologies such as artificial intelligence, big data analytics, and the Internet of Things (IoT) is improving the efficiency and productivity of AM processes. For example, machine learning algorithms can optimize the design of parts for AM, reducing material usage and improving performance. |

|

Increased use of multi-material printing |

Multi-material printing allows for the creation of parts with different properties and functionalities. This is particularly useful in the medical industry, where implants with different properties can be printed for specific patients. |

Augmented Reality (AR)

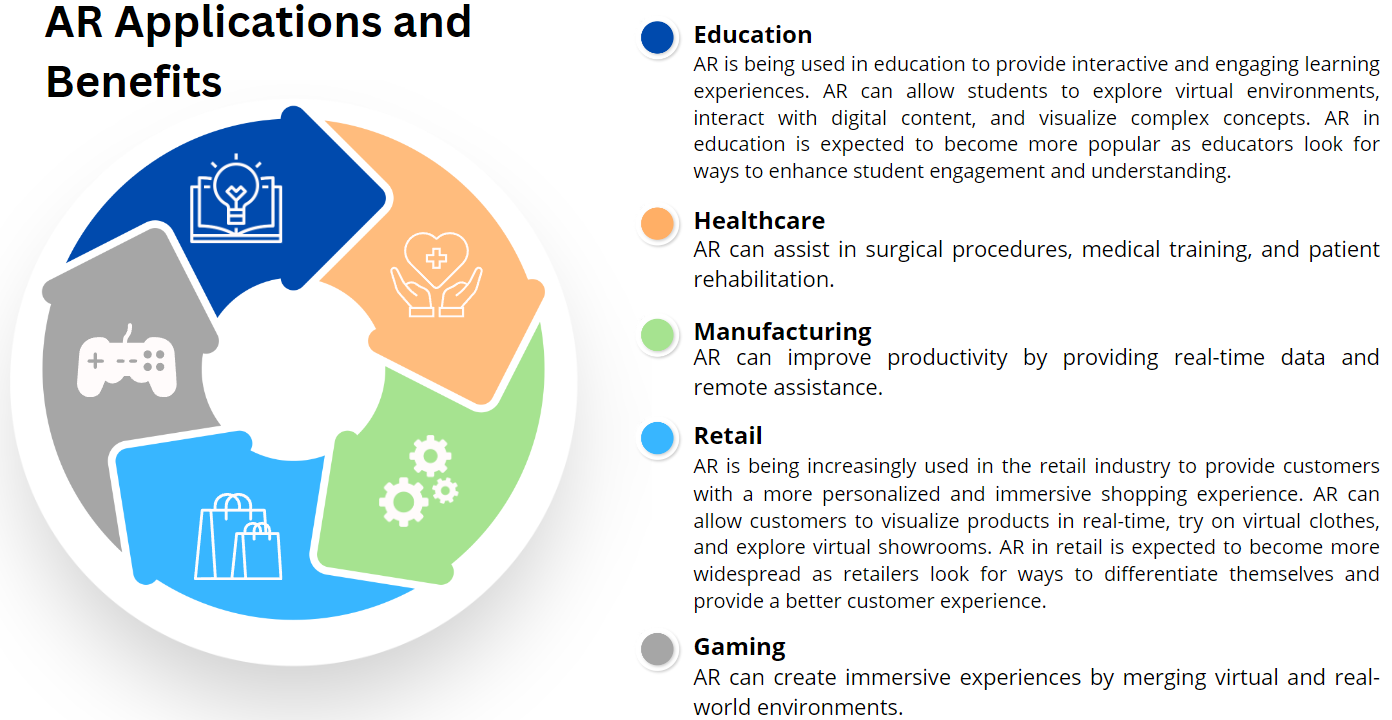

Augmented Reality (AR) is a technology that enhances our physical environment by overlaying computer-generated content onto the real world in real-time. This technology integrates digital information with the user’s physical environment and enhances their perception of reality. AR applications can be experienced through mobile devices, smart glasses, and head-mounted displays.

AR systems work by using cameras, sensors, and algorithms to recognize and track real-world objects and surfaces, and then overlay digital content on top of them. AR technology also includes various techniques such as marker-based, markerless, and SLAM-based tracking to accurately map the user’s surroundings. AR has applications in various fields, including education, gaming, healthcare, manufacturing, and retail.

AR is expected to grow in popularity and become an essential part of daily life in the coming years. The global AR market size is projected to reach $61.39 billion by 2028, growing at a CAGR of 43.8% from 2021 to 2028. The growth of AR technology is driven by the increasing adoption of AR in various industries and the development of AR hardware and software. Some key trends in Augmented Reality (AR) are presented in the following Table.

Key Trends in AR

|

Key Trend |

Details |

|

Mobile AR |

With the increasing popularity of smartphones and tablets, AR applications on mobile devices are becoming more widespread. AR on mobile devices allows users to experience AR applications without the need for specialized hardware. Mobile AR can be experienced through AR-enabled apps that use the device’s camera and sensors to overlay digital content onto the real world. |

|

AR Cloud |

The AR Cloud is a concept that involves creating a shared, persistent digital layer over the real world. The AR Cloud would allow AR applications to be more seamless and accurate by providing a common platform for AR content to be anchored to. The AR Cloud is expected to enable new use cases for AR, such as shared AR experiences, persistent AR content, and location-based AR. |

|

Wearable AR |

Wearable AR devices such as smart glasses and head-mounted displays (HMDs) provide a more immersive AR experience than mobile AR. Wearable AR devices allow users to interact with digital content hands-free, and they provide a more natural way to experience AR. Wearable AR devices are expected to become more popular in the coming years as the technology improves and becomes more affordable. |

|

AR in Retail |

AR is being increasingly used in the retail industry to provide customers with a more personalized and immersive shopping experience. AR can allow customers to visualize products in real-time, try on virtual clothes, and explore virtual showrooms. AR in retail is expected to become more widespread as retailers look for ways to differentiate themselves and provide a better customer experience. |

|

AR in Education |

AR is being used in education to provide interactive and engaging learning experiences. AR can allow students to explore virtual environments, interact with digital content, and visualize complex concepts. AR in education is expected to become more popular as educators look for ways to enhance student engagement and understanding. |

Simulation

Simulation is a key technology for developing planning and exploratory models to optimize decision making as well as the design and operations of complex and smart production systems. It is a critical Industry 4.0 technology that has become increasingly important in modern manufacturing processes. It enables companies to model and test complex systems, optimize processes, and reduce costs. Simulation can be used in various applications, including product development, design, testing, and training, among others. It could also aid companies to evaluate the risks, costs, implementation barriers, impact on operational performance, and roadmap toward Industry 4.

One of the primary benefits of simulation is that it enables companies to test various scenarios and outcomes without the need for physical prototypes, which can be time-consuming and expensive. This ability to simulate and predict performance has resulted in reduced development costs and shortened time-to-market.

Another significant use of simulation is in the optimization of production processes. By modeling the production line, manufacturers can identify bottlenecks and optimize their production flow, leading to increased productivity and reduced waste. Simulation can also help improve supply chain management by modeling the flow of goods and identifying potential issues.

Simulation also plays a crucial role in the field of predictive maintenance. By using simulation models to analyze machine performance data, manufacturers can predict when a machine is likely to fail and schedule maintenance accordingly. This can reduce downtime, increase machine uptime, and ultimately save costs.

Furthermore, simulation is an essential tool for training and education. With the ability to create realistic virtual environments, simulations can be used to train employees on new equipment, procedures, and safety protocols. This can improve safety, reduce training costs, and increase employee proficiency.

Simulation is an ever-evolving field that is constantly changing and adapting to new technological advances and industry demands. The table below presents some key trends that are currently shaping the field of simulation.

|

Key Trend |

Details |

|

Increased use of Artificial Intelligence (AI) |

AI is being used to enhance the accuracy and speed of simulations. AI algorithms can analyze large amounts of data and identify patterns that can help improve simulation models. AI can also be used to create more realistic and interactive virtual environments. |

|

Growing popularity of Digital Twins |

Digital Twins are virtual replicas of physical assets that are used to monitor, analyze, and optimize their performance. Digital Twins are being used in various industries, including manufacturing, healthcare, and energy, to improve operational efficiency and reduce costs. |

|

Simulation for Additive Manufacturing (AM) |

Simulation is becoming increasingly important in the field of AM. Simulation models can help optimize the printing process and improve the quality and strength of printed parts. Simulation is also being used to predict the behavior of materials during the printing process. |

|

Use of Cloud Computing |

Cloud computing is being used to enhance the accessibility and scalability of simulation software. Cloud-based simulation platforms can be accessed from anywhere and can handle large-scale simulations more efficiently. |

|

Increased focus on Human Factors |

Simulation is being used to study human behavior and interactions with complex systems. By simulating human responses in various scenarios, researchers can identify potential safety hazards and design more user-friendly systems. |

Overall, simulation is a critical Industry 4.0 technology that has the potential to revolutionize manufacturing and production processes. With its ability to predict outcomes, optimize processes, and improve safety, simulation is likely to become increasingly important in the years to come.

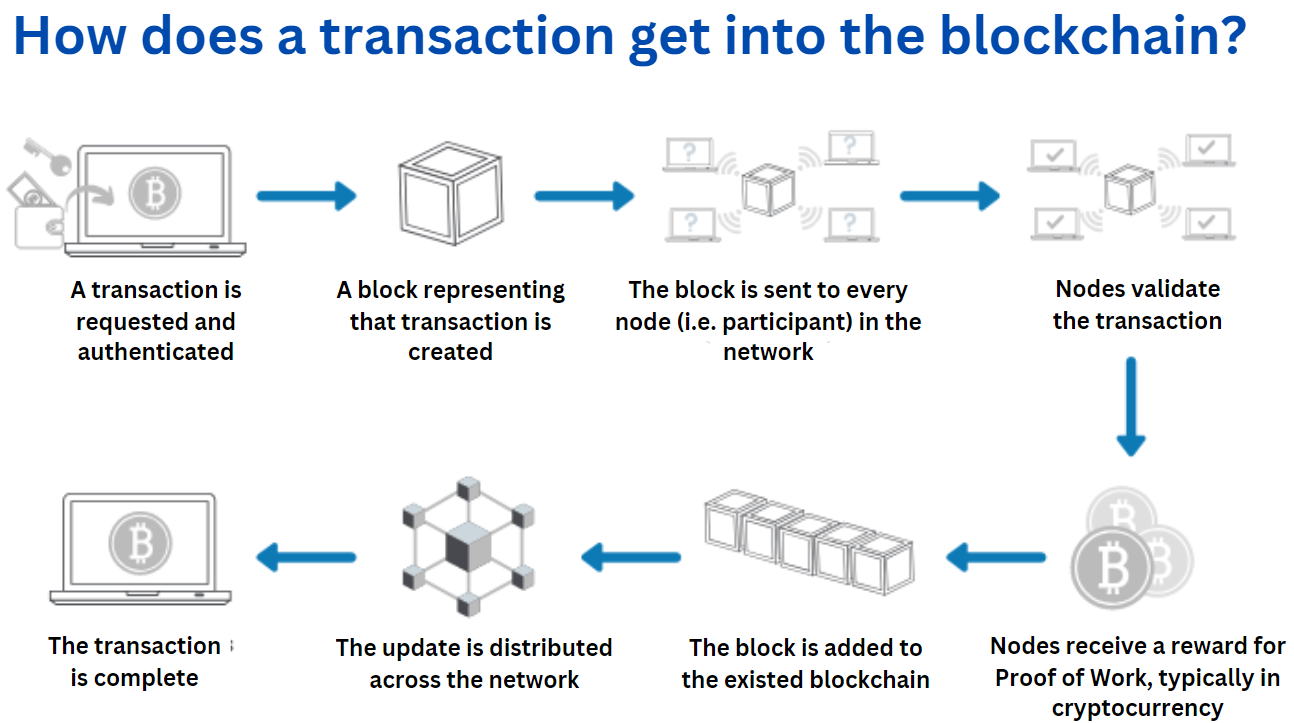

Blockchain

Industry 4.0 involves innovations with upcoming digital technologies, and blockchain is one of them. Blockchain can be incorporated to improve security, privacy, and data transparency both for small and large enterprises. Blockchain can be defined as a decentralised, distributed directory driving smart contracts and providing the opportunity to traceability aid, record management, automation for the supply chain, payment applications and other business transactions. Blockchain provides a record of almost real-time replicated between a network of business partners and is unchanging.

Blockchain transaction process

Blockchain enables decentralized data storage and management, where data is stored on a distributed network of nodes rather than a central server. This helps to improve data security and prevent data tampering. It also provides a secure and transparent way to perform transactions between parties without the need for intermediaries. This helps to reduce transaction costs and increase transaction speed.

In addition, Blockchain enables the use of smart contracts, which are self-executing contracts that automatically enforce the terms of an agreement between parties. This helps to improve contract management and reduce the risk of fraud. Recently, Blockchain is being used to improve supply chain management by providing end-to-end visibility and traceability of goods. This helps to reduce the risk of counterfeiting and improve supply chain efficiency. Finally, Blockchain is being integrated with IoT devices to provide secure and decentralized data sharing and management. This helps to improve IoT security and enable new business models.

The Table below highlights some of the key trends that are shaping the field.

|

Key Trend |

Details |

|

Interoperability |

With the growing number of blockchain platforms and networks, there is a need for interoperability between them to enable seamless exchange of data and assets. This has led to the development of projects like Polkadot and Cosmos, which aim to provide cross-chain interoperability. |

|

Decentralized Finance (DeFi) |

DeFi has emerged as one of the most promising use cases for blockchain technology. It allows for the creation of decentralized financial applications that operate on the blockchain without the need for intermediaries. Some of the popular DeFi applications include lending and borrowing platforms, decentralized exchanges, and stablecoins. |

|

Non-Fungible Tokens (NFTs) |

NFTs are digital assets that represent ownership of unique items such as art, music, or collectibles. They are stored on the blockchain, making them tamper-proof and verifiable. NFTs have gained significant attention in recent years, with several high-profile sales and auctions. |

|

Central Bank Digital Currencies (CBDCs) |

Several countries are exploring the development of CBDCs, which are digital versions of their national currencies issued by central banks. CBDCs aim to provide a more efficient and secure way of conducting transactions, while also allowing central banks to monitor and regulate the monetary system. |

|

Privacy and Security |

With the increasing use of blockchain in sensitive applications such as healthcare and finance, there is a growing need for privacy and security. This has led to the development of privacy-focused blockchains like Monero and Zcash, as well as the use of techniques like zero-knowledge proofs and homomorphic encryption. |

Cloud Computing

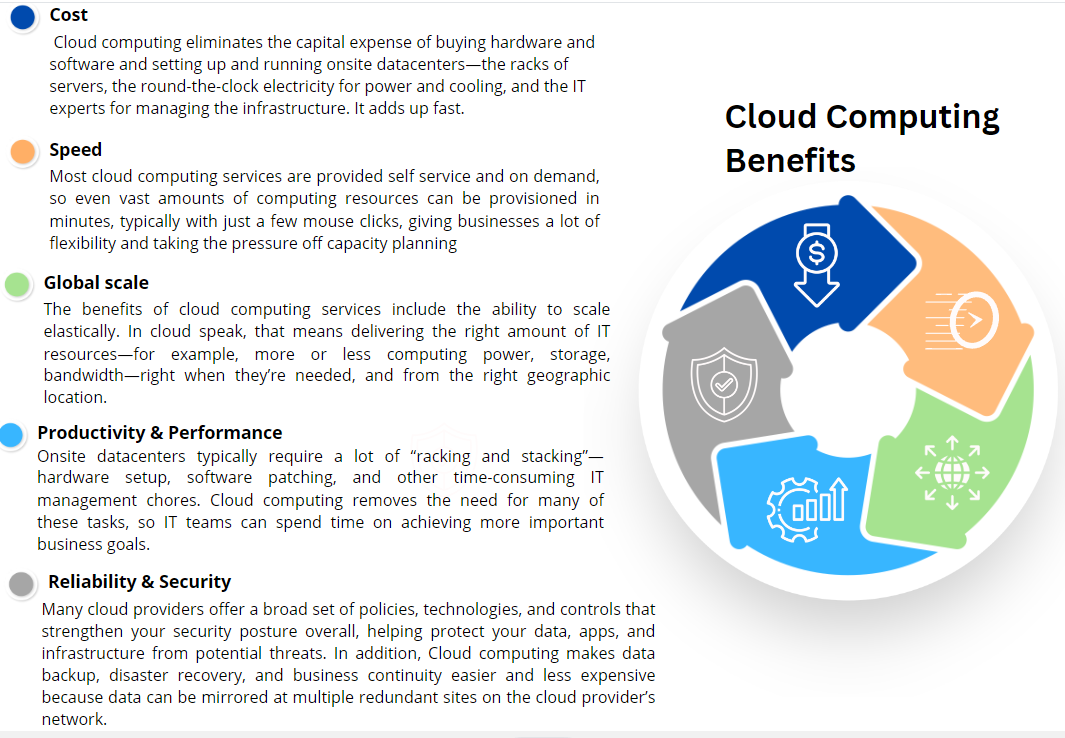

Cloud Computing is the delivery of computing services—including servers, storage, databases, networking, software, analytics, and intelligence—over the internet (“the cloud”) to offer faster innovation, flexible resources, and economies of scale.

Several different models, types, and services of Cloud Computing have been developed with different deployment, or cloud computing architecture:

- Public cloud: Public clouds are owned and operated by third-party cloud service providers, which deliver computing resources like servers and storage over the internet. Microsoft Azure is an example of a public cloud. With a public cloud, all hardware, software, and other supporting infrastructure is owned and managed by the cloud provider. You access these services and manage your account using a web browser.

- Private cloud: A private cloud refers to cloud computing resources used exclusively by a single business or organization. A private cloud can be physically located on the company’s onsite datacenter. Some companies also pay third-party service providers to host their private cloud. A private cloud is one in which the services and infrastructure are maintained on a private network.

- Hybrid cloud: Hybrid clouds combine public and private clouds, bound together by technology that allows data and applications to be shared between them. By allowing data and applications to move between private and public clouds, a hybrid cloud gives your business greater flexibility and more deployment options and helps optimize your existing infrastructure, security, and compliance.

Most cloud computing services fall into four broad categories: Infrastructure as a Service (IaaS), Platform as a Service (PaaS), Serverless, and Software as a Service (SaaS). These are sometimes called the cloud computing “stack” because they build on top of one another.

The Table below presents key trends in the field of Cloud Computing.

|

Key Trend |

Details |

|

Edge computing |

Edge computing is becoming increasingly important as organizations look to process and analyse data closer to the source of the data. This approach can reduce latency, improve data security, and enable real-time decision-making. Major cloud providers like AWS, Microsoft, and Google are offering edge computing services to support this trend. |

|

AI and machine learning |

Cloud providers are offering AI and machine learning services that enable organizations to build intelligent applications and services. These services include pre-built models for tasks like natural language processing and computer vision, as well as tools for building custom models. |

|

Cloud Security |

As more sensitive data is being stored and processed in the cloud, security has become a critical concern. Cloud providers are offering a range of security features, including identity and access management, network security, and encryption. Organizations are also using third-party tools to enhance cloud security. |

High Performance Computing

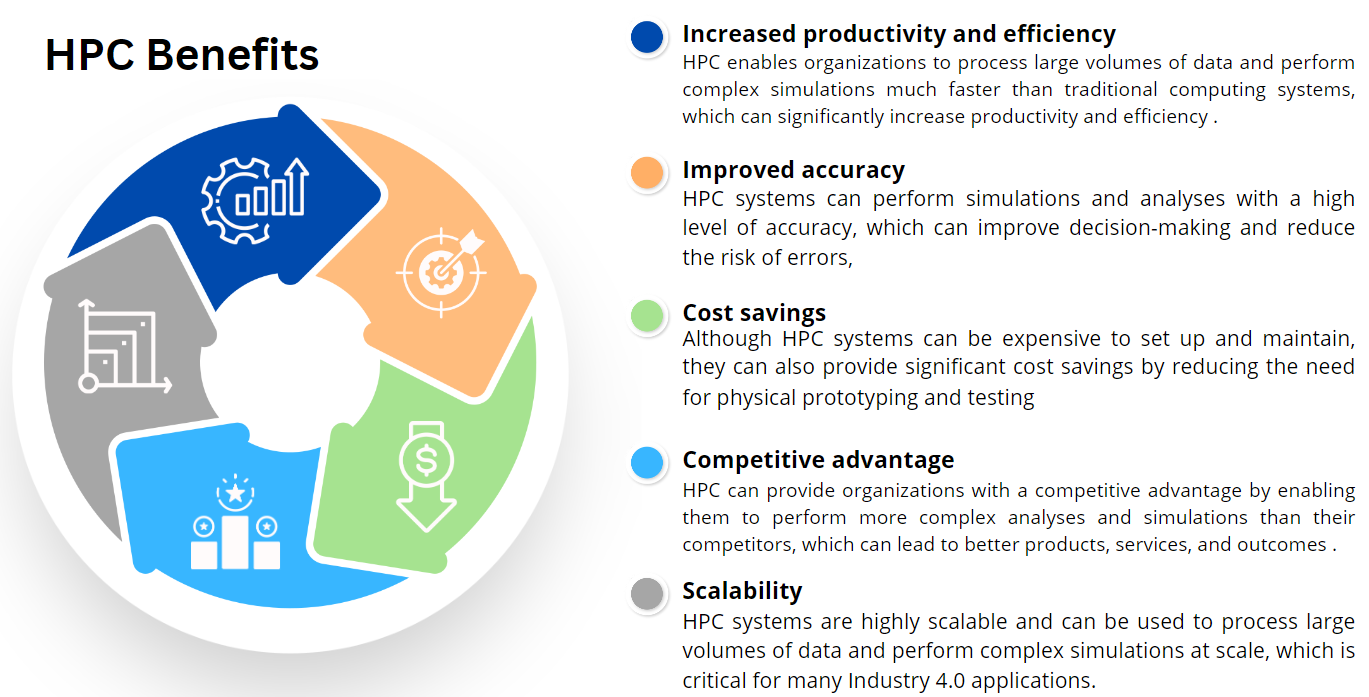

High-performance computing (HPC) is a critical technology for Industry 4.0, enabling organizations to analyse massive amounts of data and perform complex simulations at scale. HPC systems typically use parallel computing techniques and specialized hardware to deliver superior performance compared to traditional computing systems.

HPC workloads uncover important new insights that advance human knowledge and create significant competitive advantage. For example, HPC is used to sequence DNA, automate stock trading, and run artificial intelligence (AI) algorithms and simulations—like those enabling self-driving automobiles—that analyze terabytes of data streaming from IoT sensors, radar and GPS systems in real time to make split-second decisions. The key benefits of adopting HPC technologies are highlighted in the following Figure.

A standard computing system solves problems primarily using serial computing—it divides the workload into a sequence of tasks, and then executes the tasks one after the other on the same processor. In contrast, HPC leverages:

- Massively parallel computing. Parallel computing runs multiple tasks simultaneously on multiple computer servers or processors. Massively parallel computing is parallel computing using tens of thousands to millions of processors or processor cores.

- Computer clusters (also called HPC clusters). An HPC cluster consists of multiple high-speed computer servers networked together, with a centralized scheduler that manages the parallel computing workload. The computers, called nodes, use either high-performance multi-core CPUs or, more likely today, GPUs (graphical processing units), which are well suited for rigorous mathematical calculations, machine learning models and graphics-intensive tasks. A single HPC cluster can include 100,000 or more nodes.

- High-performance components. All the other computing resources in an HPC cluster—networking, memory, storage and file systems—are high-speed, high-throughput and low-latency components that can keep pace with the nodes and optimize the computing power and performance of the cluster.

HPC applications have become synonymous with AI apps in general, and with machine learning and deep learning apps in particular; today most HPC systems are created with these workloads in mind. These HPC applications are driving continuous innovation in different areas such as Healthcare, genomics and life sciences, Financial services, Government and defence and Energy. Some of the key trends shaping the field of HPC are presented below.

Key Trends in HPC

|

Key Trend |

Details |

|

Convergence of HPC with AI and big data |

The integration of HPC with artificial intelligence (AI) and big data is a major trend in the field, with HPC systems being used to process and analyze large datasets for AI applications such as deep learning. |

|

Use of cloud-based HPC |

Cloud-based HPC is becoming increasingly popular due to its scalability and flexibility, enabling organizations to quickly provision and use HPC resources as needed. |

|

Energy efficiency |

As HPC systems become more powerful, they also consume more energy. Improving energy efficiency is therefore a major trend in the field, with efforts focused on developing more efficient hardware and software solutions. |

|

Edge computing |

The use of HPC at the edge of the network, closer to where data is generated, is a growing trend in the field. This approach can reduce latency and improve the performance of real-time applications. |

|

Interoperability |

The development of standards and tools that enable different HPC systems to interoperate is a key trend in the field, enabling organizations to combine resources from multiple systems to meet their computational needs. |

Industrial Robots

Industrial robots are programmable machines designed to automate industrial tasks such as assembly, welding, material handling, and painting. They are a key technology in Industry 4.0, and their use is becoming increasingly widespread in manufacturing and other industrial applications.

The STOA in industrial robots is characterized by several key developments and trends:

- Collaborative robots: Collaborative robots, or “cobots,” are designed to work alongside human workers, sharing tasks and workspace in a safe and efficient manner. They are equipped with sensors and other safety features that allow them to operate in close proximity to humans without posing a risk of injury.

- Advanced sensors and vision systems: Advanced sensors and vision systems are being integrated into industrial robots to enable them to perform more complex tasks and operate with greater precision. These systems allow robots to detect and respond to changes in their environment, such as the position of objects, and adjust their actions accordingly.

- Artificial intelligence: Artificial intelligence (AI) is being used to enhance the capabilities of industrial robots, enabling them to learn from experience and make decisions based on real-time data. Machine learning algorithms are used to optimize robot performance and improve efficiency.

- Modular design: Modular design is becoming increasingly popular in industrial robots, allowing them to be customized and reconfigured for different tasks and applications. Modular robots can be easily adapted to meet changing manufacturing needs and can be more cost-effective than traditional fixed robots.

- Mobility: Mobile robots, including autonomous mobile robots (AMRs) and automated guided vehicles (AGVs), are becoming more common in manufacturing and logistics applications. These robots can move around a factory or warehouse independently, transporting goods and materials between different locations.

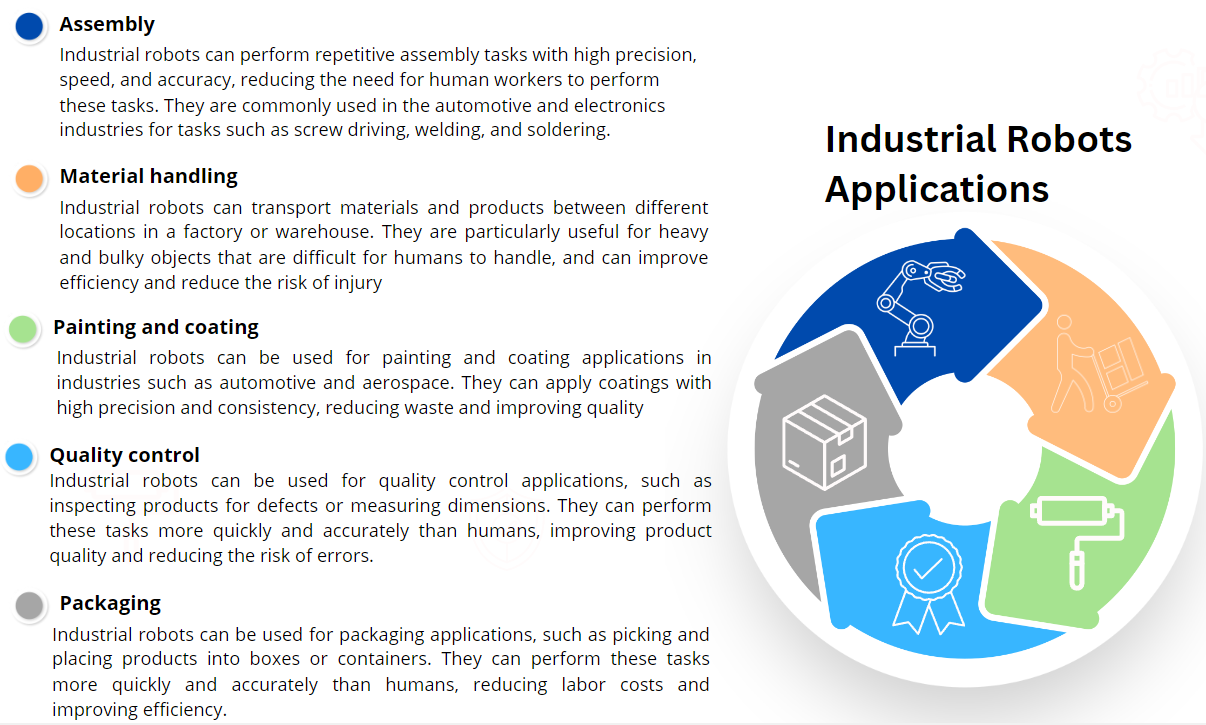

Industrial robots are used in a wide range of applications across various industries, including manufacturing, automotive, electronics, and aerospace. Some of the key applications for industrial robots are presented in the Figure below.

Key Applications for Industrial Robots

Machine-to-Machine (M2M)

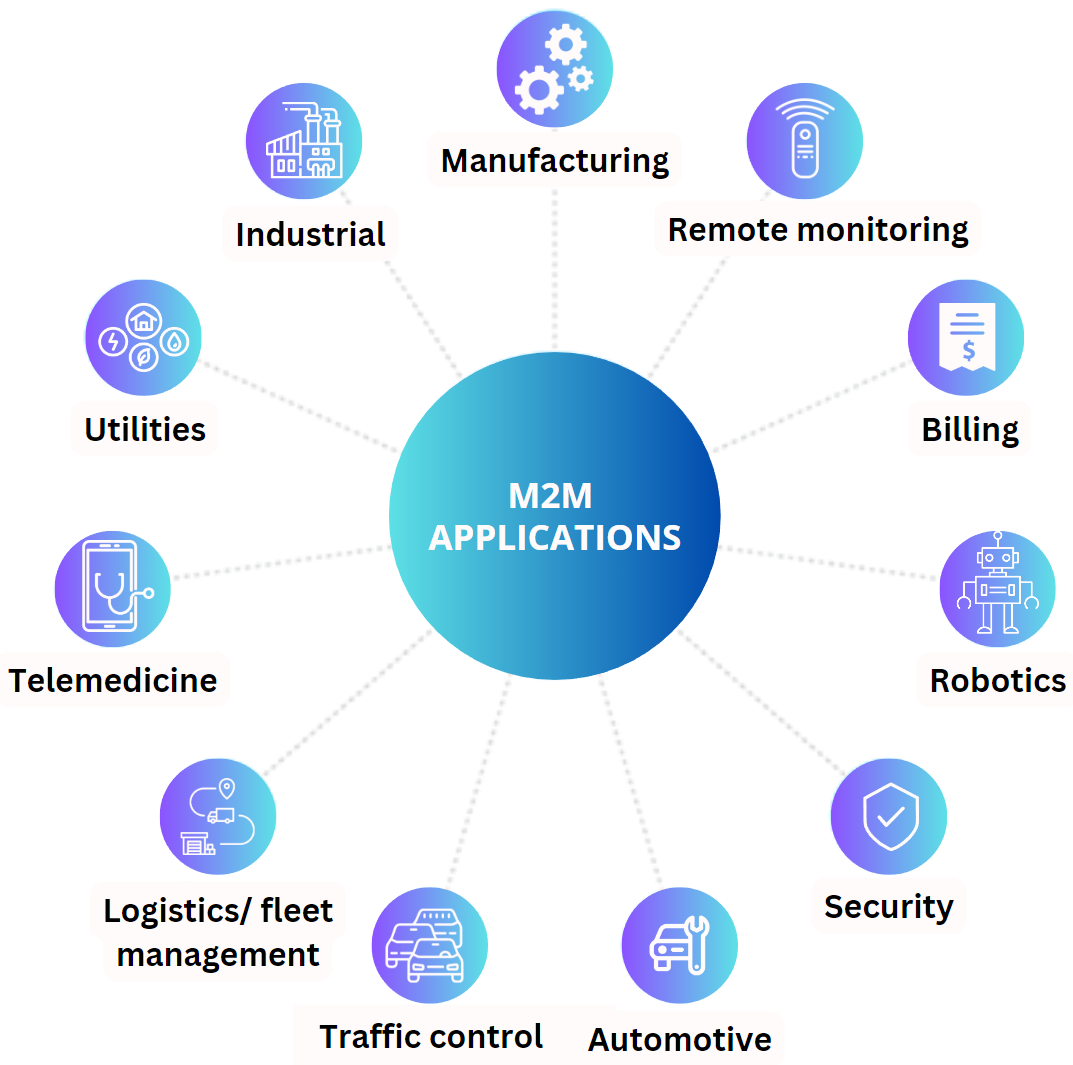

Machine-to-machine (M2M) is a broad label that can be used to describe any technology that enables networked devices to exchange information and perform actions without the manual assistance of humans. Artificial Intelligence (AI) and Machine Learning (ML) facilitate the communication between systems, allowing them to make their own autonomous choices.

M2M technology was first adopted in manufacturing and industrial settings, where other technologies, such as SCADA and remote monitoring, helped remotely manage and control data from equipment. M2M has since found applications in other sectors, such as healthcare, business and insurance.

M2M is also the foundation for the Internet of Things (IoT). The main purpose of machine-to-machine technology is to tap into sensor data and transmit it to a network. Unlike SCADA or other remote monitoring tools, M2M systems often use public networks and access methods – for example, cellular or Ethernet – to make it more cost-effective.

The main components of an M2M system include sensors, RFID, a Wi-Fi or cellular communications link, and autonomic computing software programmed to help a network device interpret data and make decisions. These M2M applications translate the data, which can trigger pre-programmed, automated actions. One of the most well-known types of machine-to-machine communication is telemetry, which has been used since the early part of the last century to transmit operational data. Pioneers in telemetrics first used telephone lines, and later, radio waves, to transmit performance measurements gathered from monitoring instruments in remote locations.

Beyond being able to remotely monitor equipment and systems, the top benefits of M2M include reduced costs by minimizing equipment maintenance and downtime, boosted revenue by revealing new business opportunities for servicing products in the field and improved customer service by proactively monitoring and servicing equipment before it fails or only when it is needed. In product restocking, for example, a vending machine can message the distributor’s network, or machine, when a particular item is running low to send a refill. An enabler of asset tracking and monitoring, M2M is vital in warehouse management systems (WMS) and supply chain management (SCM). Utilities companies often rely on M2M devices and applications to not only harvest energy, such as oil and gas, but also to bill customers – through the use of Smart meters – and to detect worksite factors, such as pressure, temperature and equipment status.

Here follow some key trends in Machine-to-Machine (M2M) communication.

|

Key Trend |

Details |

|

Growing adoption of LPWAN technologies |

Low Power Wide Area Networks (LPWAN) are becoming increasingly popular for M2M communication due to their low power consumption, long-range coverage, and low cost. Some examples of LPWAN technologies include Sigfox, LoRaWAN, and NB-IoT. |

|

Integration of Artificial Intelligence (AI) and Machine Learning (ML) |

M2M systems are increasingly incorporating AI and ML algorithms to enable intelligent decision-making and automation. For example, ML algorithms can be used to predict equipment failures and trigger maintenance alerts before a breakdown occurs. |

|

Greater focus on cybersecurity |

As the number of connected devices and M2M applications grows, so does the potential for security threats. M2M systems are implementing various security measures to protect against cyber attacks, such as secure communication protocols and authentication mechanisms. |

|

Increased use of edge computing |

Edge computing involves processing data closer to the source, rather than transmitting all data to a central server for processing. This can improve response time, reduce bandwidth requirements, and enable real-time decision-making in M2M applications. |

|

Greater emphasis on interoperability |

As M2M systems become more complex and involve a wide range of devices and protocols, interoperability between different systems is becoming increasingly important. Standardization efforts, such as the oneM2M standard, are aimed at ensuring interoperability between different M2M systems. |

Manufacturing Execution Systems (MES)

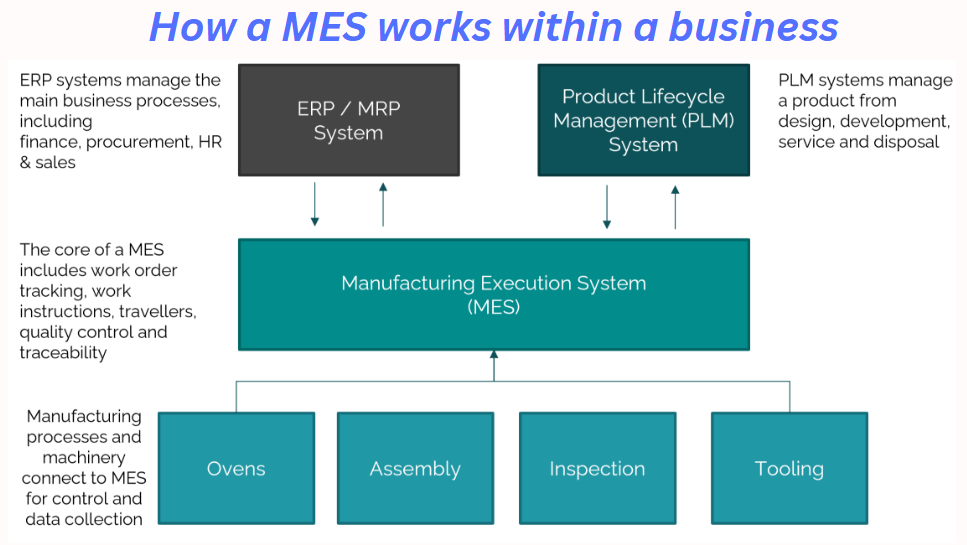

Manufacturing Execution Systems (MES) are computerized systems that provide real-time information about production processes in manufacturing plants. MES are designed to track and monitor all aspects of the manufacturing process, including material management, scheduling, quality control, and equipment performance. They can also help improve productivity, reduce waste, and increase efficiency by providing accurate, timely information to decision-makers in the manufacturing process. Modern MES are increasingly integrating with other enterprise systems, such as Enterprise Resource Planning (ERP) systems and Supply Chain Management (SCM) systems, to provide end-to-end visibility and control of the manufacturing process.

Example of a MES within a business

MES are also incorporating advanced technologies such as Internet of Things (IoT), Big Data Analytics, and Artificial Intelligence (AI) to improve process visibility and decision-making. In addition, cloud-based MES are becoming increasingly popular, as they offer benefits such as scalability, flexibility, and lower upfront costs compared to on-premises solutions.

Finally, cybersecurity is a major concern for MES, as they handle sensitive data related to production processes. MES providers are implementing various security measures, such as encryption and access controls, to protect against cyber-attacks.

Supervisory Control and Data Acquisition Systems (SCADA)

Supervisory Control and Data Acquisition (SCADA) systems are used in many industries to monitor and control processes and provide real-time data to operators and managers. SCADA systems typically consist of a network of sensors, controllers, and human-machine interfaces (HMIs) that collect and display real-time data about industrial processes. SCADA systems can be used to monitor and control a wide range of processes, from manufacturing to power generation to water treatment. They are designed to be highly scalable, and can be customized to meet the needs of different industries and applications.

SCADA systems typically have a number of key components, including Remote Terminal Units (RTUs), Programmable Logic Controllers (PLCs), and communication protocols that allow different devices to communicate with each other. These systems also rely on software to display data in a meaningful way, often using Graphical User Interfaces (GUIs) that allow operators to easily visualize the data being collected.

One of the major trends in SCADA systems is the integration of advanced analytics and machine learning algorithms, which can help operators identify patterns and anomalies in data, and make more informed decisions about process control. Another important trend is the use of cloud-based SCADA systems, which can provide greater scalability and flexibility, and allow operators to access data from anywhere in the world.

Radio-frequency identification (RFID)

Radio-frequency identification (RFID) is a technology that uses radio waves to communicate data between a reader and a tag attached to an object. The tag contains a microchip that stores data and an antenna that allows it to communicate with the reader. RFID technology has been widely adopted in various industries for tracking and managing inventory, as well as for security and access control applications.

RFID technology can be used in passive or active forms. Passive RFID tags are powered by the reader and do not have a battery, while active RFID tags have a battery and can transmit data over longer distances. RFID technology can also operate in various frequencies, such as low frequency (LF), high frequency (HF), and ultra-high frequency (UHF), with each frequency having its own advantages and limitations.

RFID technology has a wide range of applications in various industries, such as supply chain management, retail, healthcare, and transportation. For example, RFID tags can be used in the retail industry to track inventory and prevent theft, while in healthcare, RFID tags can be used to track medical equipment and patient records. In the transportation industry, RFID tags can be used to track vehicles and cargo, and in access control applications, RFID tags can be used to grant access to secure areas.

The Table below mentions some of the key trends shaping the field of RFID today.

|

Key Trend |

Details |

|

IoT integration |

RFID technology is being integrated with the Internet of Things (IoT) to enable real-time tracking and monitoring of objects. This integration allows for the collection and analysis of data that can be used to optimize processes and improve efficiency. |

|

Cloud-based solutions |

Cloud-based RFID solutions are becoming increasingly popular as they provide a scalable and cost-effective way to manage large amounts of data. Cloud-based solutions also offer improved accessibility and flexibility compared to traditional on-premise solutions. |

|

NFC technology |

Near Field Communication (NFC) technology, which is a form of RFID technology, is being used in mobile devices to enable contactless payments and other applications. NFC technology is also being used in supply chain management to track products and monitor inventory levels. |

|

Blockchain integration |

Blockchain technology is being integrated with RFID technology to create secure and transparent supply chain systems. The integration of blockchain and RFID enables the creation of an immutable record of the movement of goods, which can be accessed by all parties in the supply chain. |

Real-time Locating System (RTLS)

Real-time Locating Systems (RTLS) are technologies that use various methods to track and locate assets, people, and objects in real-time. RTLS can be used for a variety of applications, including inventory management, asset tracking, personnel tracking, and security. One of the most commonly used methods for RTLS is radio frequency identification (RFID), which uses radio waves to communicate data between a reader and a tag attached to an object or person. Another popular method is Ultra-Wideband (UWB) technology, which uses short pulses of energy to locate objects with high accuracy.

RTLS systems can be used in various industries, such as healthcare, manufacturing, logistics, and retail. For example, in healthcare, RTLS can be used to track medical equipment and personnel, while in manufacturing, RTLS can be used to monitor production processes and inventory levels. In retail, RTLS can be used to track inventory and improve the customer experience.

Recent advances in RTLS technology include the integration of IoT and cloud-based solutions, which provide real-time access to location data and enable better decision-making. In addition, advances in sensor technology, such as the use of accelerometers and gyroscopes, are improving the accuracy and reliability of RTLS systems. The Table below summarizes some of the key trends in RTLS.

|

Key Trend |

Details |

|

Integration with the Internet of Things (IoT) |

RTLS systems are increasingly being integrated with IoT technologies, which enable the real-time monitoring and tracking of assets across a wide range of industries. |

|

Use of advanced sensor technologies |

RTLS systems are increasingly using advanced sensor technologies, such as accelerometers and gyroscopes, to improve accuracy and reliability. |

|

Cloud-based solutions |

Cloud-based RTLS solutions are becoming more popular, as they provide real-time access to location data and enable better decision-making. |

|

Emergence of hybrid RTLS solutions |

Hybrid RTLS solutions, which combine multiple technologies such as RFID, UWB, and Wi-Fi, are becoming more common, as they offer improved accuracy and reliability. |

Cybersecurity

Cybersecurity refers to the practice of protecting electronic systems, networks, and data from unauthorized access, theft, or damage. It involves various techniques and technologies to secure computer systems, networks, and mobile devices from cyber-attacks, data breaches, and other malicious activities. Some of the key components of cybersecurity include cryptography, access control, threat detection and response, and security auditing. The term applies in a variety of contexts, from business to mobile computing, and can be divided into a few common categories.

- Network security is the practice of securing a computer network from intruders, whether targeted attackers or opportunistic malware.

- Application security focuses on keeping software and devices free of threats. A compromised application could provide access to the data its designed to protect. Successful security begins in the design stage, well before a program or device is deployed.

- Information security protects the integrity and privacy of data, both in storage and in transit.

- Operational security includes the processes and decisions for handling and protecting data assets. The permissions users have when accessing a network and the procedures that determine how and where data may be stored or shared all fall under this umbrella.

- Disaster recovery and business continuity define how an organization responds to a cyber-security incident or any other event that causes the loss of operations or data. Disaster recovery policies dictate how the organization restores its operations and information to return to the same operating capacity as before the event. Business continuity is the plan the organization falls back on while trying to operate without certain resources.

- End-user education addresses the most unpredictable cyber-security factor: people. Anyone can accidentally introduce a virus to an otherwise secure system by failing to follow good security practices. Teaching users to delete suspicious email attachments, not plug in unidentified USB drives, and various other important lessons is vital for the security of any organization.

Cybersecurity applications are relevant in virtually every industry that relies on electronic systems, networks, and data. Some of the main industries where cybersecurity applications are particularly important are presented in the Figure below.

One of the primary challenges in cybersecurity is the constantly evolving threat landscape. Cybercriminals are constantly developing new attack techniques and tools to bypass security measures and steal sensitive data. As a result, cybersecurity professionals must stay up-to-date with the latest trends and threats, and constantly adapt their security strategies to keep pace with the evolving threat landscape.

Another key trend in cybersecurity is the growing use of Artificial Intelligence (AI) and Machine Learning (ML) to improve threat detection and response. AI and ML algorithms can analyze vast amounts of data to identify patterns and anomalies that may indicate a potential cyber threat, and can also automate certain security tasks to improve efficiency and reduce the risk of human error.

Finally, another important trend in cybersecurity is the increasing importance of cloud security. As more organizations move their applications and data to cloud-based platforms, it is essential to ensure that these environments are secure and protected from cyber threats. More key trends are presented in the table below.

|

Key Trend |

Details |

|

Internet of Things and cloud security |

With the advent and growth of 5G networks, a new era of inter-connectivity will become a reality with the Internet of Things (IoT). This communication between multiple devices also opens them to vulnerabilities from outside influence, attacks or an unknown software bug. IoT devices – ranging from smart wearables to home appliances, cars, building alarm systems and industrial machinery – have often proven to be a bugbear for those with responsibility for cybersecurity. |

|

Work-from-home cybersecurity |

The pandemic has forced many companies to move to remote working, introducing a new set of cybersecurity challenges. Remote workers may be more vulnerable to cyberattacks as they often have less secure networks and devices. As such, organizations must ensure adequate security measures to protect their remote workers, such as multi-factor authentication, secure VPNs, and automated patching. |

|

Artificial intelligence (AI) and Machine Learning. |

AI and ML can be used to identify patterns and anomalies in data, making them useful in cybersecurity for threat detection, risk assessment, and incident response. |

|

Zero Trust Security |

Zero trust security is an approach to cybersecurity that assumes that no one is trusted, even those inside the organization. This approach relies on strict access controls and continuous monitoring to ensure that only authorized users and devices can access sensitive data and applications. |

|

Automotive Hacking |

Modern vehicles nowadays come packed with automated software creating seamless connectivity for drivers in cruise control, engine timing, door lock, airbags and advanced systems for driver assistance. These vehicles use Bluetooth and Wi-Fi technologies to communicate that also opens them to several vulnerabilities or threats from hackers. Gaining control of the vehicle or using microphones for eavesdropping is expected to rise in 2023 with more use of automated vehicles. Self-driving or autonomous vehicles use an even further complex mechanism that requires strict cybersecurity measures. |

|

Multi-Factor Authentication |

Multi-factor authentication (MFA) is a security measure that requires users to provide more than one form of authentication before they can access an account. This additional layer of security helps to protect against cyberattacks, as attackers must have access to multiple pieces of information in order to gain access. Organizations should ensure that all accounts are secured with MFA to reduce the risk of unauthorized access. Automation is becoming increasingly important in cybersecurity. Automated security processes can help reduce the time it takes to detect and respond to threats and improve the accuracy of threat detection. Automation can also reduce the reliance on manual processes, which can be time-consuming and prone to human error. |

|

International State-Sponsored Attackers |

State-sponsored attackers have become increasingly sophisticated, and organizations need to be aware that these types of attackers may target them. They must ensure adequate security measures to protect against these types of attacks, such as multi-factor authentication and real-time monitoring. |

Virtualization Technologies

Virtualization is a process that allows for more efficient utilization of physical computer hardware and is the foundation of cloud computing.

Virtualization uses software to create an abstraction layer over computer hardware that allows the hardware elements of a single computer—processors, memory, storage and more—to be divided into multiple virtual computers, commonly called virtual machines (VMs). Each VM runs its own operating system (OS) and behaves like an independent computer, even though it is running on just a portion of the actual underlying computer hardware.

It follows that virtualization enables more efficient utilization of physical computer hardware and allows a greater return on an organization’s hardware investment.

Today, virtualization is a standard practice in enterprise IT architecture. It is also the technology that drives cloud computing economics. Virtualization enables cloud providers to serve users with their existing physical computer hardware; it enables cloud users to purchase only the computing resources they need when they need it, and to scale those resources cost-effectively as their workloads grow.

Virtualization brings several benefits to data centre operators and service providers:

- Resource efficiency: Before virtualization, each application server required its own dedicated physical CPU. IT staff would purchase and configure a separate server for each application they wanted to run. Invariably, each physical server would be underused. In contrast, server virtualization facilitates runing several applications on a single physical computer without sacrificing reliability. This enables maximum utilization of the physical hardware’s computing capacity.

- Easier management: Replacing physical computers with software-defined VMs makes it easier to use and manage policies written in software. This allows the creation of automated IT service management workflows. For example, automated deployment and configuration tools enable administrators to define collections of virtual machines and applications as services, in software templates. This means that they can install those services repeatedly and consistently without cumbersome, time-consuming and error-prone manual setup. Admins can use virtualization security policies to mandate certain security configurations based on the role of the virtual machine. Policies can even increase resource efficiency by retiring unused virtual machines to save on space and computing power.

- Minimal downtime: OS and application crashes can cause downtime and disrupt user productivity. Admins can run multiple redundant virtual machines alongside each other and failover between them when problems arise. Running multiple redundant physical servers is more expensive.

- Faster provisioning: Buying, installing, and configuring hardware for each application is time-consuming. Provided that the hardware is already in place, provisioning virtual machines to run all your applications is significantly faster. You can even automate it using management software and build it into existing workflows.

The Table below presents some of the key trends shaping the field of virtualization technologies.

Key Trends in virtualization technologies

|

Key Trend |

Details |

|

Cloud-based Virtualization |

Virtual machines and applications are increasingly being hosted in cloud environments, allowing organizations to save on hardware costs, scale resources on-demand, and access data and applications from anywhere. |

|

Containerization |

Containerization is a lightweight form of virtualization that allows applications to run in isolated environments with their own dependencies. Docker and Kubernetes are examples of container platforms gaining popularity. |

|

Hyper-converged Infrastructure (HCI) |

This refers to combining multiple data centre services like computing, storage, and networking into a single hardware unit. This simplifies the management of virtualized resources by consolidating them in one solution. |

|

GPU virtualization |

Graphics Processing Units (GPUs) are being virtualized to enable the efficient allocation of resources for graphics-intensive tasks and applications, like video editing and gaming. |

|

Virtualized Network Functions (VNF) |

As part of the move towards software-defined networking (SDN), network functions are being virtualized to replace traditional hardware-based appliances. This helps organizations reduce network management complexity and scale networking services |

|

Virtual Reality (VR) and Augmented Reality (AR) |

VR devices are leveraging virtualization technology to create more realistic, immersive experiences. AR is extending the virtual world into physical spaces for education, entertainment and industrial applications. |

|

AI and Machine Learning |

Virtualization is enabling the deployment and management of AI and machine learning models across multiple platforms and devices, allowing organizations to harness the power of these technologies more efficiently. |

|

Edge computing |

As IoT devices proliferate, edge computing is becoming more crucial for reducing latency and quick data processing. Virtualization technologies enable organizations to manage resources at the edge of the network. |

Identification of Industry 4.o dimensions

As discussed in the previous section, the broad spectrum of Industry 4.0 concepts and technologies requires structuring into several levels of Industry 4.0 dimensions. Considering the project’s objectives, the following dimensions were selected to be relevant to the ‘4th Industrial Revolution’ project:

- Smart Products and Services

- Smart Production

- Smart Operation

- Business Strategy, Organization and Processes

- Employees and Competences.

Smart Products and Services

By combining the strengths of traditional industries with cutting-edge ICTs, Industry 4.0 enables the development of smart products that are integrated into a dynamic digital and physical eco-system Smart Products are a key component of an automated, flexible, and efficient “smart” production concept. Generally, smart products are products that can compute, store data, communicate, and interact with their environment. For capturing data on their own status as well as their environment, smart products typically contain various sensors, RFID, and communications interfaces. Today’s smart products can display not only their identity, but also their properties, status, histories, and lifecycle information. Their knowledge goes beyond the steps already completed and defines the steps that need to be done in the future such as upcoming maintenance operations.

Intelligent products combine physical and digital services to Smart Services. Today, it is not only the product that matters, but also the data that is generated when the product or service is used. New business models and smart services are developed based on the usage data collected and analysed. As defined in the literature, “Smart Services” are highly dependent on the type of business or context in which they are used (e.g., smart factories, internet of things, Big Data, and digitalization). The authors in note that the Smart Services enable connection between digital and physical world and increased economic efficiency. The following are major pre-conditions for establishing and providing Smart Services:

- Smart & Connected Products with electronic intelligence, such as sensors, controllers, microprocessors, and data storage chips, connected wirelessly with each other and interconnected.

- Encrypted & Secured Data Transfer and Collection utilizing Internet of Things, Internet of Services, Virtualization, Cloud Computing, and Cyber Security for collecting, transferring, securing, and storing a wide range of data.

- Data Analytics and data based intelligence with the use of computerized Big Data analysis, processing, and reassembling into Smart Data, data based intelligence, and interactive data mining to support decision-making and solve problems.

- Smart Business Models and Mindset that are customer centric and solution focused with preemptive actions to avoid unpleasant experiences.

Smart Products & Services – widely adopted technologies

|

Smart Products & Services Dimension |

Big Data Analytics |

|

Artificial Intelligence |

|

|

IIoT, Communication and Networking |

|

|

Cybersecurity |

|

|

Sensors and Actuators |

|

|

Cloud |

|

|

RFID and RTLS |

|

|

M2M |

Smart Production

With Industry 4.0, production becomes highly automated and distributed. Smart factories use context-sensitive manufacturing techniques to deal with production turbulence in real time with decentralized data and communication structures for optimum management of production processes. In the Smart Factory concept, manufacturing relevant information is collected, distributed, and accessible at any time and from anywhere in real time. The smart factory can be defined as an environment in which a production process and a logistics process largely take care of themselves without the need for human intervention. Using the Internet of Things, cyber-physical systems (CPS) link the physical and virtual worlds through communication via an IT infrastructure.

A key element of Smart Production is digital modelling, which is combined with smart data collection, storage, and processing. This ensures the delivery of information and the efficient use of resources with the smart production concept. People, information systems, and production systems must work collaboratively in real-time. The integrated systems produce a huge amount of data which is processed, analysed, and integrated into decision-making models. A company’s progress in the area of Smart Production is measured using the following criteria: Equipment Infrastructure, IT Systems, Digital Modelling and Data Usage.

Smart Production & Operation – widely adopted technologies

|

Smart Production & Operation |

Data Analytics |

|

Artificial Intelligence |

|

|

Industrial Robots |

|

|

Simulation |

|

|

Communication and Networking |

|

|

Cybersecurity |

|

|

Additive Manufacturing |

|

|

Virtualization Technologies |

|

|

Sensors and Actuators |

|

|

Cloud |

|

|

RFID and RTLS |

|

|

Mobile Technologies |

Smart Operation

Industry 4.0 Smart Operation refers to the use of advanced technologies such as Internet of Things (IoT), Artificial Intelligence (AI), Big Data analytics, and Cloud Computing to optimize industrial processes and operations. In Industry 4.0 Smart Operations, machines and systems are interconnected and communicate with each other in real-time, enabling them to make autonomous decisions based on data analytics and machine learning. This results in more efficient and cost-effective manufacturing processes, increased productivity, and improved product quality.

Smart Operation – widely adopted technologies.

|

Smart Operation |

IoT |

|

AI |

|

|

Big Data Analytics |

|

|

Cloud Computing |

One of the key technologies that underpin Industry 4.0 Smart Operations is the IoT, which allows machines, sensors, and other devices to communicate with each other and share data in real-time. IoT devices can collect data on various aspects of manufacturing processes, such as temperature, pressure, and vibration, and transmit this data to centralized systems for analysis.

Another important technology is Artificial Intelligence (AI), which can be used to analyse the vast amounts of data generated by IoT devices and other sources and derive insights that can be used to optimize manufacturing processes. AI can be used to develop predictive maintenance systems, which can anticipate and prevent machine breakdowns before they occur, saving time and money.

Big Data analytics is also a critical technology in Industry 4.0 Smart Operations, as it enables manufacturers to analyse large volumes of data from multiple sources and gain insights into manufacturing processes and customer preferences. This can help manufacturers to optimize their supply chain, reduce waste, and improve product quality.